Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

Geosynthetic clay liner is a kind of anti leakage earthwork synthetic material that applicable for artificial lake water, garbage landfill, underground garage, roof garden, pool, oil depot and chemicals yard and other places. As geosynthetic clay liner manufacturer known, they are widely used in these following area:

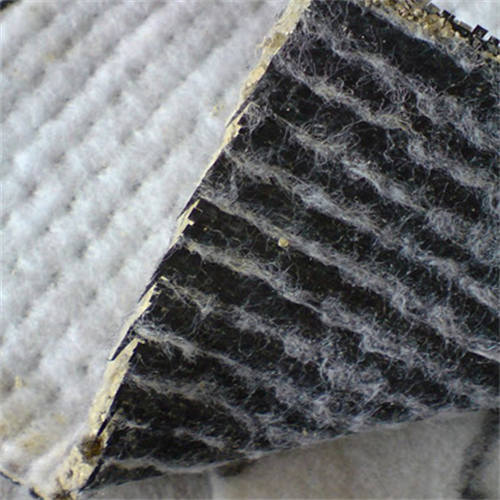

Geosynthetic clay liner manufacturer is also known as sodium bentonite composite waterproof pad manufacturer. Geosynthetic clay liner is to create a strongly swelling sodium bentonite filling inside between special composite geotextile and fleece. The waterproof bentonite cushion made with the acupuncture method can form many small fiber spaces. This prevents the bentonite particles from flowing in one direction, when it hits water, it can form a uniform, high-density, colloidal waterproof layer on the base, effectively preventing water leakage, the geosynthetic clay lining is suitable for artificial seawater, landfill, underground car park, roof garden, swimming pool, oil tank and chemistry area.

Specifications:

Product Name: Geosynthetic Tonliner

Material: Sodium Bentonite, Special Composite Geotextile and non-woven fabric

Width: 6m

Length: 30m

Weight (grams / square meter): 4kg / m2 6kg / m2.

Note: We also accept customize specifications. Because we are a geosynthetic clay liner manufacturer.

Features:

Light.

Small volume

Excellent flexibility

Simple construction

Permanently waterproof

Good sealing performance

Environmental protection

Geosynthetic clay liner can be used for pond, it is suitable for drilling lining and applicable for landfill. Geosynthetic clay liner is mainly used for waterproofing construction, it can also be used for artificial lake.

Waterproofing principle

The mineralogical name of bentonite is montmorillonite. Natural bentonite is divided into two main categories according to its chemical composition: sodium-based and calcium-based. Bentonite has the property of swelling when exposed to water. Generally speaking, when calcium-based bentonite expands, its expansion is only about three times of its own volume. However, when sodium-based bentonite meets water, it can absorb 5 times its own weight of water and expand to more than 15-17 times its volume. Locking sodium bentonite in the middle of two layers of synthetic materials can play a protective and reinforcing role. And make the geosynthetic clay liner has a certain overall shear strength.

Construction method and precautions

| No. | Item | Technical Index | |||

| GCL-NP | GCL-OF | GCL-AH | |||

| 1 | GCL (g/㎡) | ≥4000 and not less than the specified value | ≥4000 and not less than the specified value | ≥4000 and not less than the specified value | |

| 2 | Swelling Index of Bentonite (ml/2g) | ≥24 | ≥24 | ≥24 | |

| 3 | Absorption of Blue ( g/100g) | ≥30 | ≥30 | ≥30 | |

| 4 | Tensile Strength (N/100mm) | ≥600 | ≥700 | ≥600 | |

| 5 | Elongation at Maximum Load % | ≥10 | ≥10 | ≥8 | |

| 6 | Peel Strength(N/100mm) | Non Woven and Woven Fabrics | ≥40 | ≥40 | / |

| PE Film and Non Woven Fabrics | / | ≥30 | / | ||

| 7 | Permeability Coefficient (m/s) | ≤ 5.0×10^-11 | ≤ 5.0×10^-12 | ≤ 1.0×10^-12 | |

| 8 | Hydrostatic Pressure Resistance | 0.4MPa, 1h, no seepage | 0.6MPa, 1h, no seepage | 0.6MPa, 1h, no seepage | |

| 9 | Filtration Loss (ml) | ≤ 18 | ≤ 18 | ≤ 18 | |

| 10 | Durability of Bentonite | ≥20 | ≥20 | ≥20 | |

Geosynthetic clay liners are widely used in artificial lakes, roof gardens, swimming pools, landfills, oil depots and chemical dumps. We at Huisen, the leading geosynthetic clay liner manufacturer, are often asked various questions about geosynthetic clay liners. Now, we have listed below the questions frequently asked by our customers for your reference when purchasing. If you have any questions, you can also contact us directly and we will be happy to receive your inquiries.

Geosynthetic clay liners (GCL) are an established sealant in the geo-environmental industry. They are used in landfill applications as caps and base liners, as secondary containment for fuel storage facilities, as well as in various other containment structures such as dams, canals ,rivers and lakes.

Sodium Bentonite Clay

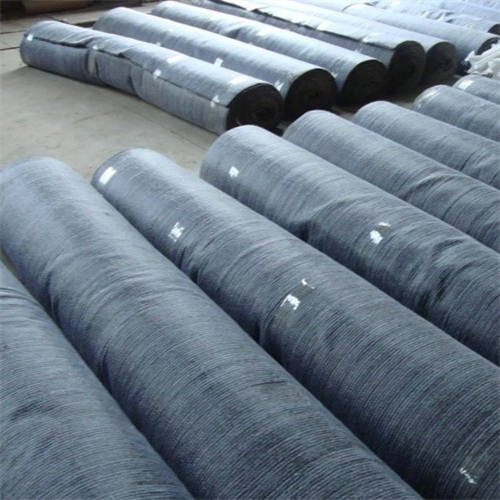

Geosynthetic clay liners (or GCL) represent the newest subset of geosynthetic materials. They are factory-made rolls of thin layers of bentonite clay that are embedded between two geotextiles or bonded with a geomembrane. Structural integrity is maintained through stamping, sewing, or physical bonding.

How do I install a geosynthetic clay liner?

Huisen now tells you from the perspective of a geosynthetic clay liner manufacturer that the installation of a geosynthetic clay liner requires the following three steps.

Step 1 – Excavate the area for the liner. The excavated area should be at least 12 inches deeper than the finished grade.

Step 2 – Prepare the area for the installation of the liner. Make sure the subgrade is free of any rocks and debris.

Step 3 – Install the geosynthetic clay liner.

What makes GCL different from other geosynthetic products is that it incorporates a woven geotextile for dimensional stability and is reinforced for increased internal shear strength. Huisen GCL offers an array of different features for applications requiring a wide range of load and slope conditions in mining, landfills and pond projects.

Bentonite clay contains natural minerals like calcium, magnesium, and iron that can provide additional benefits. Bentonite clay is formed from volcanic ash. It takes its name from Fort Benton, Wyoming, where it is found in large numbers.

| Characteristic | Geosynthetic Clay Liners (GCL) | Compacted Clay Liners (CCL) |

|---|---|---|

| Material | Bentonite clay, adhesives, geotextiles and/or geomembranes | Native soils or blends of soil and bentonite clay |

| Construction | Factory manufactured and then installed in the field | Construction and/or amended in the field |

| Thickness | ~ 6 mm | 300 to 900 mm |

| Hydraulic conductivity of clay[6] | 10−10 to 10−12 m/s | 10−9 to 10−10 m/s |

| Speed and ease of construction | Rapid, simple installation | Slow, delicate and complicated compaction works |

| Installed cost | $0.05 to $0.10 per m2 | Highly variable (estimated range $0.07 to $0.30 per m2) |

| Experience | Construction quality assurance and quality control are critical | Highly workforce dependent |

Get newest quote, customize geosynthetics solution or anything! If you are looking for an affordable solution, turn to Huisen.

Fill in your details and Huisen will get back to you in no time.