Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

China’s production costs are low.

China’s supply chain system is well developed.

China’s production capacity is large.

China’s labor costs are very low.

China’s workers are highly qualified.

Stable products at low prices.

Scale effect reduces production costs.

Chinese companies are well versed in the export process.

China enjoys a lower import tax rate.

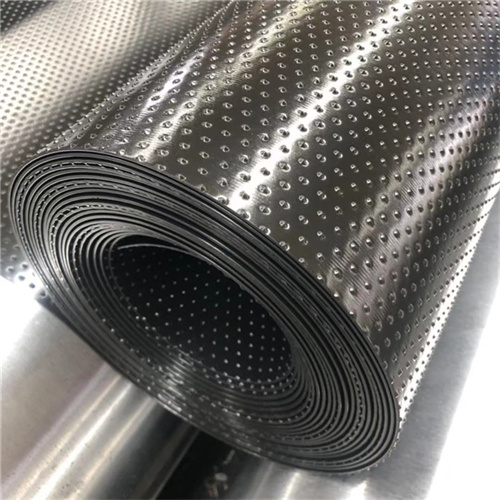

Drainage Net, also called Composite Geonet, is a two or three-layer three-dimensional drainage geosynthetic product which are often made with polypropylene PP or regenerated HDPE (geonet) and covered with double-sided thermally heat-bonded nonwoven geotextile on both sides or one side. It has excellent performance than traditional draining gravel. So it becomes a good alternative for gravel in drainage application. Our drainage net is widely used for landfill, railway system drainage, road drainage, tunnel and retaining wall.

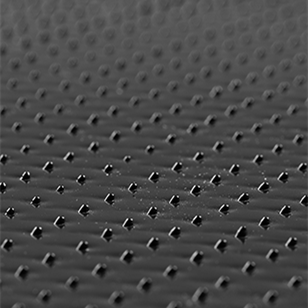

Textured geomembrane surfaces can upload friction among the geomembrane liner and different items, for example, the geotextile. Because the textured geomembrane surfaces are rough, the friction pressure is high, the geomembrane liner can't slip on the slop, and be strong there.

Huisen is likewise a geomembrane manufacturer.The textured geomembrane liner may be executed 8m extensive and feature a clean region at every side,20cm easy region. This region may be used to weld the geomembrane liner together, and smooth for the engineers to alter the welding region and size. It is essential and workable.

Composite geomembrane is a type of waterproof material made up of geotextile and geomembrane. There are many types of composite geomembrane that compoite geomenbrane manufacturer could supply: one textiles, one membrane, two textiles, one membrane, several textiless, several membranes, and so on. Composite geomembrane is mainly used for drainage and reinforcement, has the advantages of acid and alkali resistance, good infiltration resistance, tensile strength, resistance to shattering. tear, burst strength, etc., mainly for waterproof purposes.

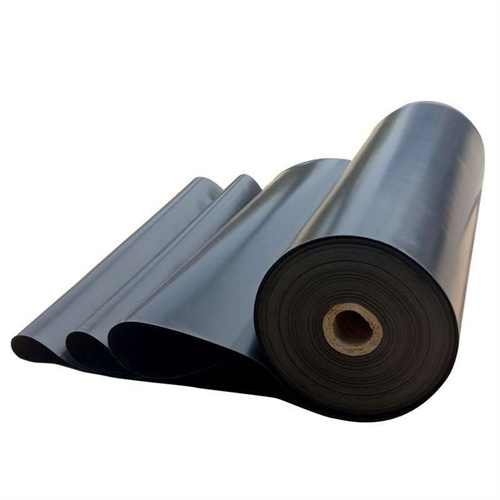

Do you know what is a geomembrane, and how are they used? As a flexible geomembrane manufacturer in China, Huisen knows very well about geomembrane.

Huisen is a geomembrane manufacturer from China, we own our own factory. You can customize your geomembrane here, we provide OEM service and had passed CE certification.

Geomembranes are impermeable geosynthetics that, until recently, were mainly used as canal and pond liners. However, modern technology has broadened liner applications to include landfills, wastewater treatment lagoons, oil and gas exploration (including hydraulic fracturing or “fracking”), aquaculture, irrigation ponds and remediation. In many of these applications, a nonwoven geotextile is used as a cushion to protect the geomembrane. In general, geomembrane liners offer excellent puncture resistance and can withstand a wide range of chemicals and temperatures. They are also highly flexible and conform well to the subgrade.

A geomembrane may seem like a medical experiment gone awry, but its uses and applications are both varied and fascinating. Geomembranes are synthetic membranes or barriers used to control the migration of fluids in an engineered design, structure, or system. They consist of relatively thin continuous polymer sheets that are sometimes made by infusing geotextiles with sprays of asphalt, elastomer or polymer. This means that their applications to geotechnical engineering and other industrial customers are endless.

Geomembranes are used in environmental, hydraulic, transportation, and oil and gas applications as well as in the waste industry. The most common type are continuous polymer sheets. When larger geomembranes are required, they are thermally or chemically fused at the joints for strength and durability. The size of the geomembrane is fully customizable, so it can be as small as a backyard fish pond or as large as a football field if needed.

Basically, geomembranes are used wherever loss of material is not allowed, whether it is clean water, sewage, steam, soil, hazardous materials, or any other substance that is not permitted. Does not need to escape from its designated space. Because the fluids (and even vapors) that flow, accumulate, frozen and stationary can be so devastating if not handled properly, these geomembranes have allowed industries to continue to develop and support many more projects than before.

The main functions of geomembrane are.

1、Integrate the function of anti-seepage and drainage in one, and have the function of isolation and reinforcement at the same time.

2、High compound strength, high peel strength and high puncture resistance.

3、Strong drainage capacity, large friction coefficient and small linear expansion coefficient.

4、Good aging resistance, wide range of adapting to environmental temperature, stable quality.

Warp-knitted composite reinforced waterproof geotextile has superior water barrier, durability and protection. As a result, geomembranes are widely used in environmental, hydraulic, transportation, oil and gas applications, and waste treatment industries. The most common type is a continuous polymer sheet. When larger geomembranes are required, they are thermally or chemically fused together at the seams to increase strength and durability.

Geomembrane for landfill

Geomembranes are ideal for use in landfill plugs, landfill covers, landfill liners, temporary landfill closures and more due to their ability to effortlessly adapt to differential sedimentation in the stack waste. Its high elongation and durability make PVC the best environmental coating for these applications. First used as a base layer for municipal waste containment and landfill closures to prevent stormwater drainage.

Geomembrane for caps and closures

Geomembrane covers are commonly used to protect material from water ingress and to prevent material loss from wind or water erosion. Mulching can also help combat odor. Long-term applications are sealing caps or landfill caps. Another application is to extend the service life of the roofs of above-ground storage tanks.

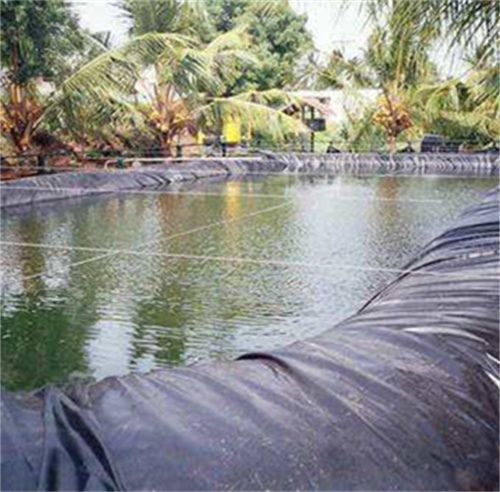

Geomembrane for pond liner

Coatings made from the same material can also show significant differences in performance. geosynthetics such as HDPE coatings have many advantages as pond liners. These liners are strong and flexible, and highly resistant to chemicals and corrosion. They are the most durable and long-lasting polyethylene liners on the market. Welded together, they form a permanent seal in the field.

Geomembrane for mining

In this application, the HDPE geomembrane lining serves as a separation barrier and is also the most important component in heap leaching. The geomembrane must withstand chemical attacks, point loads from typically high pile load conditions, site-specific topography, site-specific climatic conditions and site-specific conditions. It can help with seepage and sewage systems, prevent small particles and gravel from being produced.

Geomembrane for secondary containment

From small tanks to entire depots, secondary containment areas are an important part of tank lining protection. Geomembranes have been proven to perform well in hundreds of secondary containment applications. For exposed applications. Conductive geomembranes can be used to detect damage after installation and as part of a regular maintenance program. Geomembranes are widely used in secondary containment applications such as chemical storage tank spill protection.

Geomembrane for canal liners

Geomembranes are commonly used to control leaks in waterways. There are many types of geomembranes available for this application, including PVC, HDPE, LDPE, CSPE and EPDM geomembranes. These geomembranes often require protection and several protection options are available, including compacted soil, concrete or shotcrete.

Geomembranes for oil & gas containment

HDPE textured geomembrane liners have a rough surface on one or both sides that can highly increase the coefficient of friction, making them more suitable for design work on steep slopes and vertical projects, maximizing the effective volume of the geomembrane to increase frictional resistance and other chemical and physical properties as smooth HDPE geomembranes. HDPE textured geomembranes exhibit excellent shear strength and the highest multi-axial performance with superior high shear strength, large friction angles, outstanding elongation and the highest coefficient of friction at the interface surface.

| Item | value |

Type | Geomembranes |

Warranty | More than 5 years |

After-sale Service | Online Technical Support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement |

Project Solution Capability | graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, Others |

Application | fish farm pond liner |

Design Style | Asian |

Place of Origin | Shandong China |

Product Name | HDPE Geomembrane |

Brand Name | Huisen(geomembrane mannfacturer) |

Model Number | GH-2s |

Application | Landfill,Dam,Pond Liner,Fish Pond,Aquaculture,Mining,Reservoir, Wastewater Treatment System,etc. |

Material | HDPE LDPE LLDPE EPDM EVA |

Function | Antiseepage,Anti-leakage,Waterproof, Reinforcement |

Certification | ISO9001/ISO14001/BV/SONCAP |

Payment | T/T,L/C,D/A,D/P,Western Uoion |

Package | Woven Bags.Keep it away from fire |

Geomembrane products have various specifications, such as one fabric, one fabric, two fabric, two fabric, two fabric, two fabric and multi-film. There are models from 200g/m2 to 1000g/m2, etc. The geomembrane manufacturers can also produce geomembranes individually according to the requirements of users according to their actual conditions.

The construction materials used in infrastructure projects should be as durable as possible. Landfills, wastewater treatment lagoons, oil and gas exploration must specify and use the best possible geomembranes that have been designed for project and protect applications. We at Huisen, flexible geomenbrane manufacturer, are often asked various questions about geomenbranes. Now, we have listed the frequently asked questions by customers below for your reference in purchasing. If you have any doubts, you can also contact us directly, we are happy to receive your inquiries.

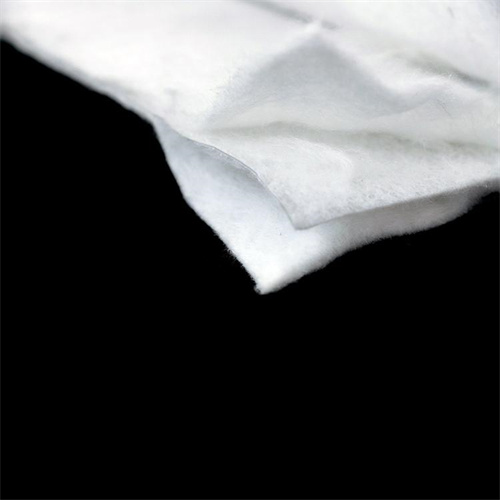

A geomembrane is very low permeability synthetic membrane liner or barrier used with any geotechnical engineering related material so as to control fluid (or gas) migration in a human-made project, structure, or system. Geomembranes are made from relatively thin continuous polymeric sheets, but they can also be made from the impregnation of geotextiles with asphalt, elastomer or polymer sprays, or as multilayered bitumen geocomposites. Continuous polymer sheet geomembranes are, by far, the most common.

Geomembranes are impermeable geosynthetics that, until recently, were mainly used as canal and pond liners. However, modern technology has broadened liner applications to include landfills, wastewater treatment lagoons, oil and gas exploration (including hydraulic fracturing or “fracking”), aquaculture, irrigation ponds and remediation. In many of these applications, a nonwoven geotextile is used as a cushion to protect the geomembrane. In general, geomembrane liners offer excellent puncture resistance and can withstand a wide range of chemicals and temperatures. They are also highly flexible and conform well to the subgrade.

Huisen is not only a geotextile manufacturer, but also a geomembrane manufacturer. So we are clear that they are difference in performance and use:

Geomembrane is made of high-density polyethylene, which is used to prevent seepage, while the geotextile is made of non-woven fabric. Geotextile is a permeable geosynthetic material made of synthetic fibers through needle punching or weaving. It is mianly used in roads, railways, water conservancy, large buildings, etc. Geomembrane is a plastic film, which is used in roads, railways, water conservancy, large buildings, power plant ash dam construction, soil and water conservation, etc.

In one case, the cost of the geomembrane CQA only was around US$20,000 per hectare ($8,500 per acre). Electrical leak location surveys for geomembrane liners typically cost US$3,500 to US$6,000 per hectare ($1,500 to $2,500 per acre).

Want to get Huisen geomembrane manufacturer quote? Feel free to contact us at any time!

A typical geomembrane has the consistency of a thicker garbage bag and is measured to be 60 mils thick. This material, known as 60 mil HDPE, is the industry standard.

Geomembranes are synthetic membrane liners or barriers that are used to control fluid migration in an artificial project, structure, or system. They consist of relatively thin, continuous polymer sheets, sometimes made from geotextiles with asphalt, elastomer or polymer sprays.

HDPE (High Density Polyethylene)

Geomembrane HDPE liners are resistant to many different solvents and are the most widely used geomembrane liners in the world. Although HDPE geomembrane is less flexible than LLDPE, it offers higher specific strength and can withstand higher temperatures.

Composite geomembrane is a type of geosynthetic that is made up of more than two types of materials, such as geotextiles (or fiberglass mesh), polymers (such as PE geomembrane, EVA geomembrane), etc. It uses the geotextile as a layer of hydraulic conductivity, the geomembrane as a waterproof layer, made of composite geomembrane with extrusion by rolling or pouring and hot melt adhesive. It has functions and advantages of geotextiles and geomembranes.

Get newest quote, customize geosynthetics solution or anything! If you are looking for an affordable solution, turn to Huisen.

Fill in your details and Huisen will get back to you in no time.