Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

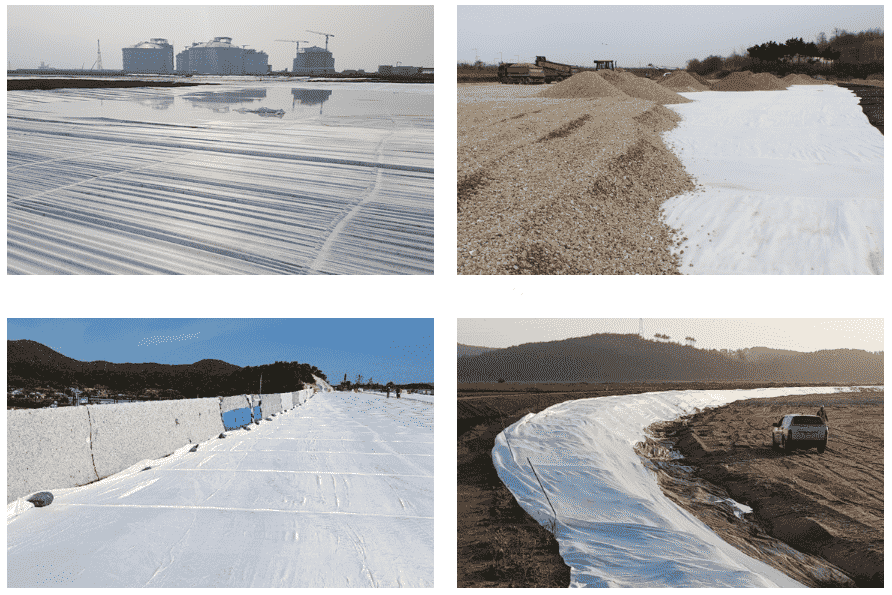

Short fiber needle punch geotextiles consist of PET / PP fibers that are intertwined by needling. The fibers that get their strength through entanglement. Fibrebonded geotextiles have an excellent water flow rate and are used for the filtration of soil fines for drainage applications, including trench drains, as perforated pipe casing, for erosion control and combined with three-dimensional structures for precast drains. Contact Huisen geotextile manufacturer to get your best quote today!

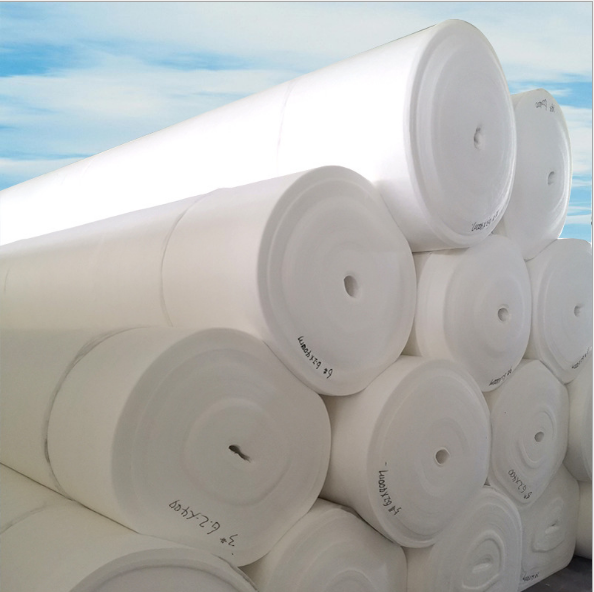

PET long fiber nonwoven geotextile is a needled geotextile made of 100% polyester continuous filament with a maximum width of 6 m. These synthetic fibers are processed into flexible and porous fabrics with standard weaving machines or woven from a random nonwoven fabric. Nonwoven fiber geotextiles are porous to the flow of liquid due to their manufacturing level and also within their thickness, but to a very different extent. PET long fiber geotextile has a very high melting point and very high UV resistance and has many applications in filtration and separation, for protection and for drainage.

Huisen are also a woven geotextile manufacturer. Woven geotextile is made of polyester woven geotextile and polypropylene geotextile. A geotextile is composed of two or more threads, strips or other components that are usually vertically woven together. The woven geotextile structure is stable, and the technical parameters are in line with standards. Filters, insulation, reinforcement, protection and other requirements of various geotechnical purposes.

Huisen is a professional geotextile manufacturer and designer. Geotextile is one of the new geosynthetic materials. It is a water-permeable geosynthetic made of polyester or polypropylene by punching or weaving. The width of the geotextile is usually 4-6 meters., The length is usually 50-100 meters. Both woven and non-woven geotextile. The filament geotextile belongs to the geotextile.

If you are looking for an affordable geotextile solution, you can turn to Huisen. As a leading geotextile manufacturer in China, Huisen knows very well the characteristics of each type of geotextile.

1. High strength, due to the use of plastic fiber as raw material, geotextile can maintain full strength and ductility in both wet and dry condition.

2. Corrosion resistance, in different degrees of acidity and alkalinity of the soil and water can also play a long good performance.

3. Good water permeability. This is because there are voids between the fibers of geotextile, so it has good water permeability.

4. Good anti-microbial property. It is difficult to be harmed by microorganisms and insects.

5. Construction is convenient, because the geotextile material is soft and flexible, and the quality is light, so it is convenient for transportation, laying and construction.

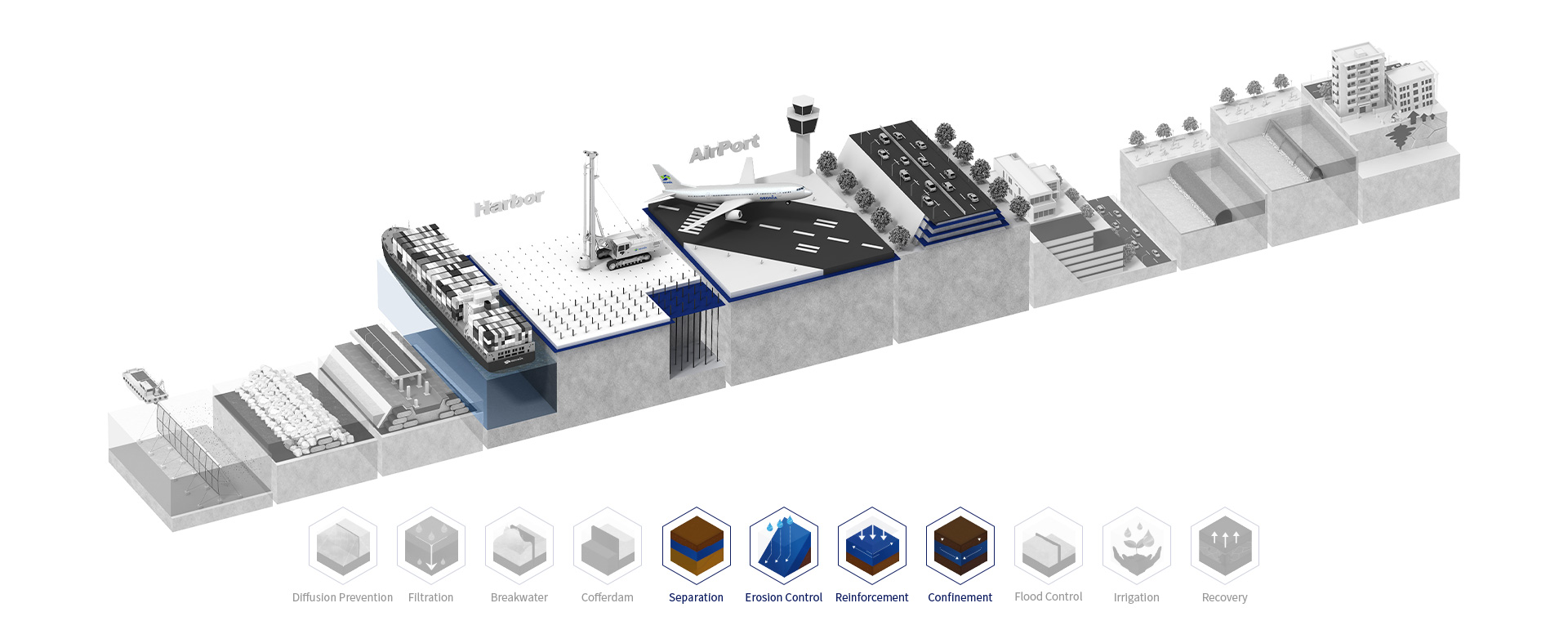

What are geotextiles used for? In general, geotextiles help build the infrastructure. Its use is determined by its function. Let’s examine seven features and ways in which geotextiles can be used.

Separation

This application is primarily intended for roads where different soil materials have been incorporated into the construction.

Stabilization

Engineers can place geotextiles on loose soil, especially during construction, until the soil is firm enough to be used as a subgrade.

Reinforcement

Since different textiles have different thicknesses depending on the manufacturing technique, they can be used to ensure the stability of earthworks.

Filter

Geotextiles are equally capable of holding the material as it is permeable. They can be used in dams and similar situations. They hold particularly small soil particles when the water is drained.

Drainage

Geotextiles are characterized by their permeability. It could ensure that water travels within the soil under controlled conditions.

Sealing

Geotextiles protect sensitive infrastructure. It has a role to play is in sealing.

Moisture Barrier

Though permeable, geotextiles, if strategically installed, can help retain moisture in the ground. Geotextiles are applicable because they save just the right amount of water.

Geotextiles are versatile in their practical applications. Its use enables projects to run smoothly. Let’s look at some uses of geotextiles.

1. Road works

During road works, some excavations loosen the soil. Geotextile applications are used for drainage. This means that the property is in good condition to start construction.

2. Agriculture

Transposition, especially on large farms, may be impossible during the rainy season.Geotextile nonwovens help with sludge control so that agricultural products leave the farms on time.

3. Retaining Wall

When used on retaining walls, geotextiles act as reinforcements.

4. Riverbanks and Coastlines

River banks are prone to severe soil erosion. One way to get the situation under control is to use geotextiles. All geotextiles that are needed to prevent erosion are a professional installation by a professional.

5. Construction

Concrete used in construction must dry at a certain rate in order to maintain the structural integrity of a building. Geotextiles pass water at a rate that allows the concrete to dry slowly and evenly.

| Item | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | Remarks |

| Mass per unit area Deviation, % | 8 | 8 | 8 | 8 | 7 | 7 | 7 | 7 | 6 | 6 | 6 | |

| Thickness, mm ≥ | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3 | 3.3 | 3.6 | 4.1 | 5 | |

| Range, deviation, % | -0.5 | |||||||||||

| Breaking strength, KN/m ≥ | 2.5 | 4.5 | 6.5 | 8 | 9.5 | 11 | 12.5 | 14 | 16 | 19 | 25 | Longitudinal and transverse directions |

| Elongation at break, % | 25~100 | |||||||||||

| CBR top breaking strength, KN ≥ | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4 | |

| Equivalent pore size 0 (0 ),mm | 0.07~0.2 | |||||||||||

| Vertical penetration coefficient,cm/s | Kx(10~10) | K=1.0 to 9.9 | ||||||||||

| Tearing strength,KN≥ | 0.08 | 0.12 | 0.16 | 0.2 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.6 | Longitudinal direction |

1) The specifications are based on the quality of the unit area. When the actual specification is between the adjacent specifications in the table, the corresponding assessment index will be calculated by interpolation method; when the range is beyond the table, the assessment index will be determined by negotiation between supply and demand.

2) The standard value is according to the design or agreement.

3) The above technical data is subject to change without notice.

4) Other specifications can be produced according to customer requirements.

The construction materials used in infrastructure projects should be as durable as possible. Architects, engineers, and road contractors must specify and use the best possible geotextiles that have been designed for road project applications. We at Huisen, one-stop geotextile manufacturer, are often asked various questions about geotextiles. Now, we have listed the frequently asked questions by customers below for your reference in purchasing. If you have any doubts, you can also contact us directly, we are happy to receive your inquiries.

A geotextile is a synthetic fabric that is used for drainage, soil improvement and erosion control in construction projects. Different geotextiles have different textures that ensure permeability. Geotextiles are an essential feature when working with floors. Geotextile manufacturers weave or weave polymers to make geotextiles. The type of polymers used to make geotextiles can be polyester or polypropylene. The making of geotextiles can be mechanical and even involve chemicals, or it can just be good old-fashioned weaving or weaving. Process creates a different type of geotextile.

Geotextiles are divided into three different categories. These categories describe the way the geotextile was made.

Woven Fabric Geotextile

As the name suggests, this category of geotextiles is woven like some pieces of clothing. When the weaving technique is applied, the geotextile looks different. Pattern that distinguishes it from the other varieties. The technology ensures that the threads run horizontally and vertically. You can recognize this formation by the final result after weaving.

Non-woven geotextiles

Non-woven geotextiles have their own style. Continuous filament yarn construction. The manufacturer must apply special effects through chemical or mechanical processes to achieve results The expected result is that the fabrics will have different thicknesses depending on the technique used.

Knitted geotextile

Knitted geotextiles have a knitted construction The weaving technique is used to make geotextiles, in In In a way, it also involves the application of fabric. It takes a certain amount of knowledge of a particular weave to achieve uniformity, and machine weaving provides that consistency.

Generally, woven geotextiles have higher strength values, while nonwovens have higher flow rates and permittivity.

Geotextiles are a thin and strong membrane fabric that is used to strengthen the soil and prevent damage. Geotextiles are mainly used in road construction, especially to fill the gaps between roads to improve the soil structure. also build in difficult places.

Geotextiles are typically made from synthetic fibers such as polyester or polypropylene, which form a flexible, porous fabric that can provide strength and stability. There are three basic forms: Weaving: similar to looting. Pierced needle: resembles felt.

The cost of geotextiles has a wide range. In this industry market, $200 rolls are standard for low-grade textiles. Woven geotextile fabric with high strength ratings can cost upwards of $3,500, depending on the size of the roll.

Geotextile membranes can be used as the filtration mechanism. In many cases, drains become clogged with debris, causing flooding and other problems. When using a geotextile membrane, water penetrates through the membrane, but other deposits or larger particles are prevented. enter the drainage system.

Some geotextiles are made of plant-based fibers. After a period of time, they decompose so that the plants can be anchored in the soil.

Geotextiles are typically used in construction projects (especially civil projects like road construction), while landscape fabrics are typically used in agriculture for weed abatement.

Get newest quote, customize geosynthetics solution or anything! If you are looking for an affordable solution, turn to Huisen.

Fill in your details and Huisen will get back to you in no time.