Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

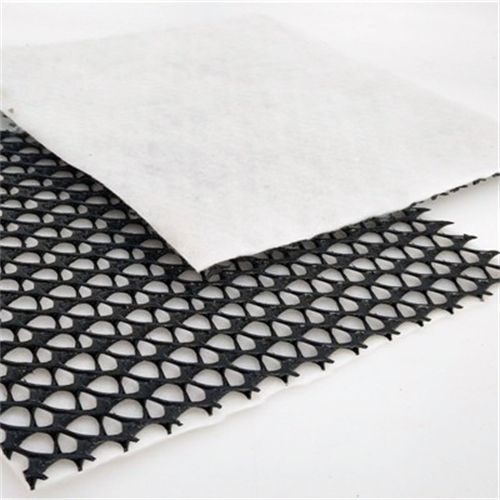

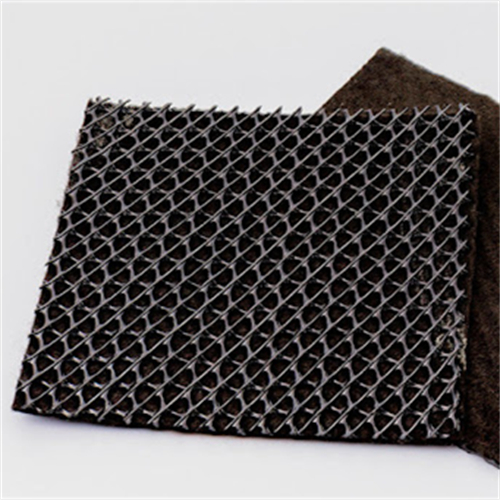

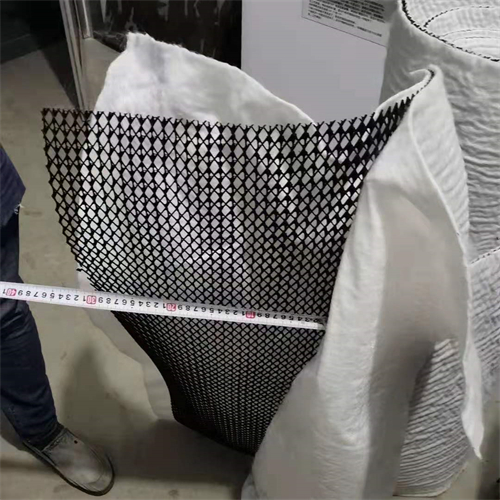

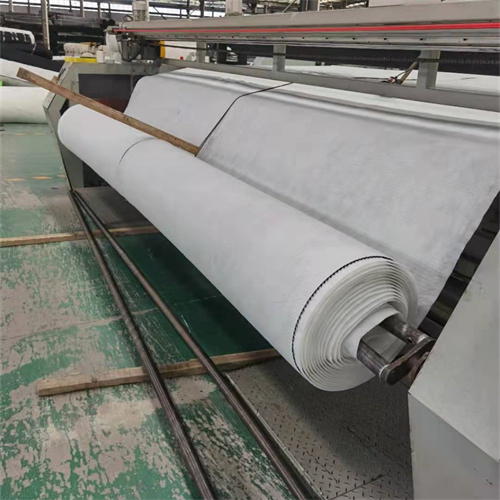

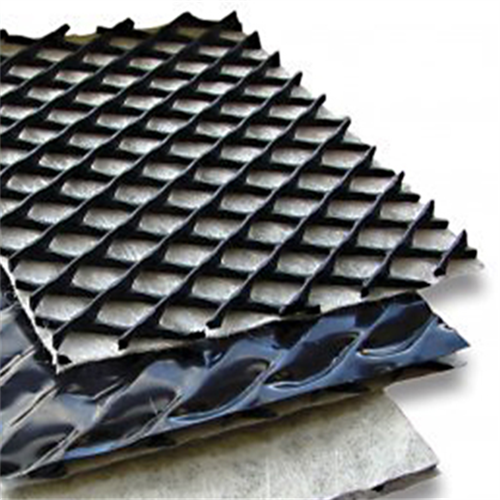

Drainage Net, also called Composite Geonet, is a two or three-layer three-dimensional drainage geosynthetic product which are often made with polypropylene PP or regenerated HDPE (geonet) and covered with double-sided thermally heat-bonded nonwoven geotextile on both sides or one side. It has excellent performance than traditional draining gravel. So it becomes a good alternative for gravel in drainage application. Huisen composite drainage net is widely used for landfill, railway system drainage, road drainage, tunnel and retaining wall.

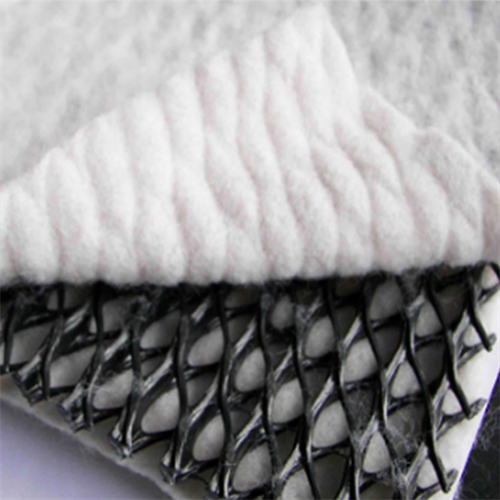

Composite Drainage Net is a new type of dewatering geotechnical material, which the raw material is HDPE and manufactured via particular extrusion forming technique. It has three levels, the inner fillet has strong rigidity, arrange longitudinal to form dewatering channel, the upper and bottom fillet form support to avoid geotextile inserting into dewatering channel, that means even if under high load it can also keep good dewatering property. It is the best dewatering material currently who has below function:" filter -- dewatering -- ventilate -- protect".

Composite drainage net is a new type of drainage geotechnical material. It is made of high-density polyethylene (HDPE) and processed by a special extrusion molding process, and has a three-layer special structure. As a leading composite drainage net manufacturer, it is our responsibility to provide the highest quality composite drainage mesh to the world.

When composite drainage net manufacturer produce it, it will be consisted with a three-dimensional structure of plastic mesh bonded on both sides with a permeable geotextile, which can replace the traditional sand and gravel layer and is mainly used for the drainage of landfills, roadbeds and tunnel interiors.

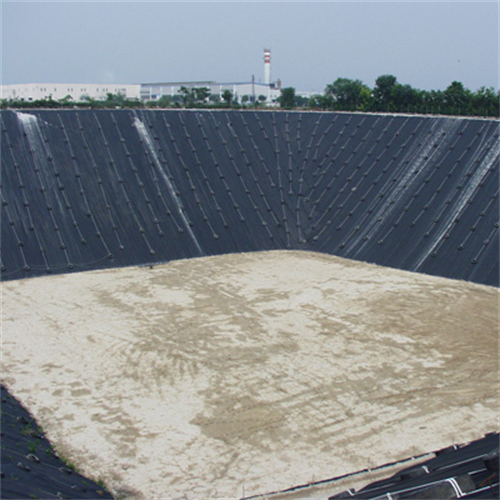

The composite drainage network has a significant effect in drainage engineering. Mainly used in

Huisen are composite drainage net manufacturer, so we know it well. The composite drainage net (also known as three-dimensional geotechnical drainage board, tunnel drainage water board, and drainage water board) is composed of a three-dimensional structure of plastic net double-sided bonded with water-permeable geotextile, which can replace the traditional sand and gravel layer, and is mainly used for garbage filling. Drainage of buried sites, roadbeds and inner walls of tunnels.With the development of modern industry, the requirements for environmental cleanliness are getting higher and higher, so the need for composite drainage networks is more urgent.

Features:

1. Strong drainage (equivalent to one meter thick gravel drainage).

2. High tensile strength.

3. Reduce the chance of geotextile embedding in the mesh core and maintain long-term stable drainage.

4. Long-term high-pressure load (can withstand compression load of about 3000Ka).

5. Corrosion resistance, acid and alkali resistance, long service life.

6. The construction is convenient, the construction period is shortened, and the cost is reduced.

Drainage of stagnant water

The composite drainage net can be placed between the foundation and the substrate, draining water between the foundation and the substrate, blocking capillary water and effectively incorporating it into the edge drainage system. This structure automatically shortens the drainage path of the foundation, and the drainage time is greatly reduced, and it enables the use of a smaller amount of selected foundation materials (i.e., materials with more fines and lower permeability). The service life of the road can be extended.

Isolation

The placement of drainage net in the subgrade prevents subgrade fines from entering the subgrade (i.e., it acts as a barrier). The aggregate subgrade will, to a limited extent, enter the upper part of the geomembrane. In this way, the composite geotechnical drainage network also has a potential role in limiting the lateral movement of the aggregate subgrade, and in this way it acts similarly to the reinforcing effect of a geogrid. In general, the tensile strength and rigidity of composite geodrainage mesh is superior to that of many geogrids used for foundation reinforcement, and this limiting effect will improve the support capacity of the foundation.

Replacing drainable foundations

When the road ages and cracks form, most of the rainwater enters the cross section. In this case, a drainage network is laid directly under the road surface in place of a drainable foundation. The drainage network can collect the water first before it enters the foundation/subgrade. And a membrane can be wrapped around the bottom end of the drainage network to further prevent water from entering the foundation. For rigid road systems, this structure allows the road to be designed with a higher drainage coefficient Cd. Another advantage of this structure is the potential for more uniform hydration of the concrete (research on the extent of this advantage is ongoing). For both rigid and flexible road systems, this structure is able to extend the life of the road.

Helps mitigate the effects of frost heave

In cold climates, laying a drainage network can help mitigate the effects of frost heave. If the freezing depth is deep, the geonet can be laid at a shallower location in the subgrade to act as a capillary action blockage. It is also often necessary to replace the subgrade with a granular subgrade that is less susceptible to frost heave, extending down to the frost depth. Frost-swellable backfill can be filled directly on top of the drainage network up to the foundation ground line. In this case, the system can be connected to the drainage outlet so that the water table is at a depth equal to or below this. This potentially limits the development of ice crystals and eliminates the need to limit traffic loads during spring ice thaw in cold regions.

Property | Unit | BC63/D200 | BC70/D200 | BC80/D200 | BC90/D200 | Test Standard |

Hydraulic conductivity (MD) | m2/s | 2.8×10-3 | 3.2×10-3 | 4.0×10-3 | 5 x10-3 | ASTM D4716 |

Puncture Resistance | KN/m | 0.17 | 0.17 | 0.17 | 0.17 | ASTM D7005 |

Thickness | mm | 6.3 | 7 | 8 | 9 | ASTM D5199 |

Density | g/cm-3 | 0.94 | 0.94 | 0.94 | 0.94 | ASTM D1505 |

Carbon Black Content | % | 2 | 2 | 2 | 2 | ASTM D1603 |

Tensile strength (MD) | kN/m | 8 | 10 | 12 | 14 | ASTM D7199 |

Hydraulic conductivity (MD) | m2/s | 8 | 10 | 12 | 14 | ASTM D4716 |

Unit weight | g/m2 | 200 | 200 | 200 | 200 | |

Geotextile type | Continuous filament non-woven geotextile | |||||

Composite drainage net is widely used in drainage projects for railroads, highways, tunnels, municipal projects, reservoirs, slope protection, etc. We, Huisen, are a professional composite drainage net manufacturer, and are often asked various questions about composite drainage net. Now, we have listed the frequently asked questions from our customers below for your reference when purchasing. If you have any questions, you can also contact us directly, and we will be happy to receive your inquiries.

It is an engineered drainage product that consists of a molded polymer core and a fully encapsulated laminated geotextile. It is an effective alternative to drainage pipes and stone systems that

Enables the collection and conveyance of groundwater. It is often used in modern drainage systems for golf courses, sports fields and residential yards.

With decade of years of development, Huisen has been an international composite drainage net manufacturer and solution provider. Huisen composite drainage net has been installed on many projects around the world for over a decade with a proven track record. Extruded HDPE net drainage cores are designed to withstand extremely high compressive loads with minimal settlement and elastic recovery rates approaching 100%. Drainage composites with monofilament cores compress significantly at relatively low pressures, which can lead to significant reductions in surface settlement and flow rates.

All of Huisen composite drainage net have been tested with compressive loads between 20 and 200kPa to determine the flow rate capacity in accordance with EN ISO 12958. Flow rates at higher compressive loads are available on request.

When designed, installed and maintained in accordance with the published literature most Huisen Geotextiles and Geocomposites are sufficiently durable to achieve a design life of at least 100 years in most typical soil conditions.

Get newest quote, customize geosynthetics solution or anything! If you are looking for an affordable solution, turn to Huisen.

Fill in your details and Huisen will get back to you in no time.