Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

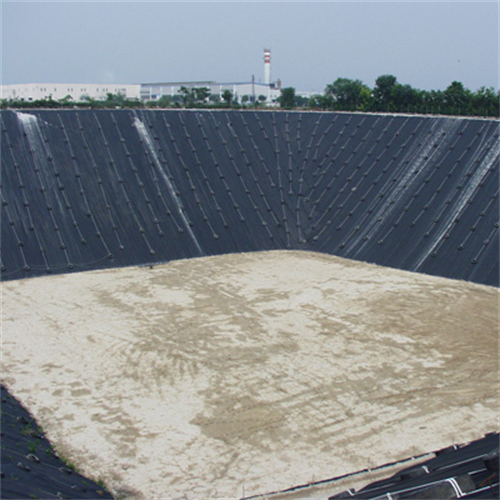

HDPE geomembrane liner is a high-density polyethylene liner used primarily for environmental containment applications. This liner offers a unique combination of flexibility, strength, and chemical resistance, making it a popular choice for a wide range of applications, including landfill linings, pond linings, and mining.

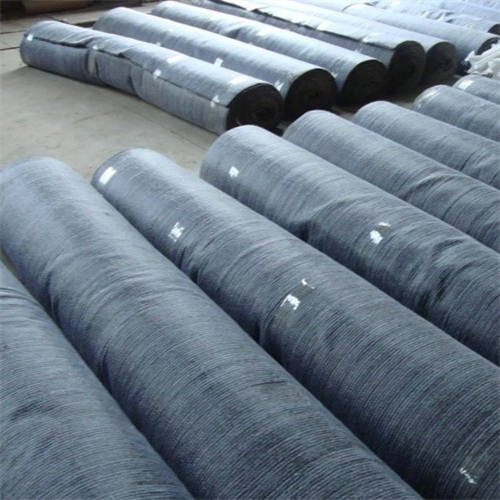

HDPE geomembrane is produced from high-density polyethylene resin. The production process involves the extrusion of the resin into sheets or rolls. These sheets are then welded together to form a continuous barrier.

| Application | Description |

|---|---|

| Landfills | Acts as a barrier to prevent contaminants from leaching into the ground. |

| Ponds & Lagoons | Prevents water loss and contamination. |

| Mining | Used to contain chemicals and solutions used in mining operations. |

While HDPE is one of the most popular geomembranes, there are others like LLDPE (Linear Low-Density Polyethylene) and PVC (Polyvinyl Chloride). Here’s a simple comparison:

| Geomembrane Type | Flexibility | UV Resistance | Chemical Resistance |

|---|---|---|---|

| HDPE | Moderate | High | High |

| LLDPE | High | Moderate | Moderate |

| PVC | High | Low | Low to Moderate |

When considering the use of HDPE geomembrane liner for a project, one of the crucial factors is the cost. The price can vary based on several factors, including the thickness of the liner, the size of the project, and the manufacturer.

| Thickness | Price Range (per square meter) |

|---|---|

| 0.5mm | $0.5 – $0.7 |

| 1.0mm | $0.8 – $1.2 |

| 1.5mm | $1.4 – $1.8 |

| 2.0mm | $1.9 – $2.5 |

Different brands offer HDPE geomembrane liners, and their prices can vary based on the quality, reputation, and additional services they provide. Here are some notable brands in the market:

While the liner’s price is a significant component, installation can sometimes be equally or even more expensive. Installation costs depend on:

On average, installation can range from $1 to $3 per square meter, depending on the above factors.

While looking for the most affordable option might be tempting, it’s essential to consider the long-term benefits of investing in a high-quality liner. Quality liners, though priced higher, can offer longer lifespans, better performance, and fewer maintenance issues.

HDPE geomembrane liners have gained widespread acceptance in various industries due to their robustness and versatility. While HDPE remains a primary material of choice, there are distinct types of these liners based on manufacturing techniques, applications, and additional treatments.

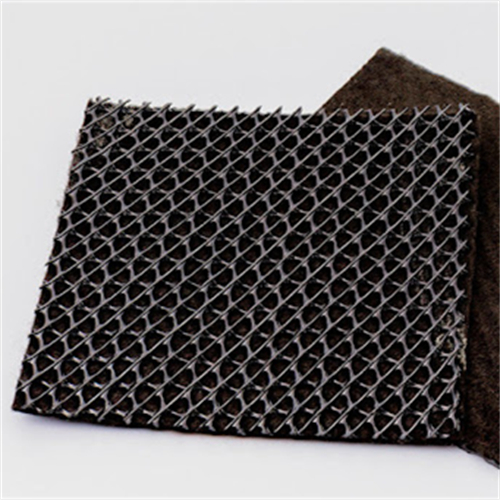

To improve frictional performance, especially on slopes, HDPE liners can be manufactured with textured surfaces. These textures can either be single-sided or double-sided.

Advantages:

The most traditional type, smooth HDPE liners are often chosen for their flexibility and ease of installation.

Advantages:

LLDPE (Linear Low-Density Polyethylene) geomembranes offer greater flexibility than HDPE. They’re especially useful in situations where more elongation is required.

| Feature | HDPE | LLDPE |

|---|---|---|

| Flexibility | Moderate | High |

| Tensile Strength | High | Moderate |

| Elongation at Break | Lower | Higher |

For projects where the geomembrane will be exposed to prolonged sunlight, UV-stabilized HDPE liners are a perfect choice. They have specific additives that protect them from the harmful effects of ultraviolet rays.

For aesthetic or functional reasons, HDPE geomembranes are available in various colors. For instance, a white surface might be chosen to reflect sunlight and reduce the heat aging of the material.

Price Range: The cost of HDPE geomembrane liners can vary based on type, thickness, and treatments. Generally, textured and UV-stabilized liners may be slightly more expensive, ranging from $0.9 to $2.8 per square meter, depending on the brand and region.

HDPE geomembrane liners are versatile products that serve a plethora of functions in various industries. Their unique properties make them invaluable in different scenarios. Here are some primary functions of these liners:

One of the primary functions of an HDPE geomembrane is to act as a containment barrier. Whether it’s for landfills, ponds, or hazardous material storage, these liners prevent the contained material from escaping and potentially harming the environment.

Special dual-layer HDPE geomembrane systems can be employed to detect leaks. These liners are typically integrated with a layer of conductive material. If a breach occurs, it can be located by detecting the path of the electrical current.

HDPE liners also serve to protect the environment from potentially harmful materials. In waste management or mining applications, they shield groundwater and surrounding ecosystems from contaminants.

In applications like landfills, HDPE liners not only contain waste but also facilitate the collection of methane gas. This gas can then be treated or utilized as a renewable energy source.

In areas prone to erosion, especially those near water bodies, HDPE geomembranes can be used to stabilize soil and prevent erosion, protecting both infrastructure and the environment.

In construction, HDPE liners can act as vapor barriers, preventing moisture from seeping into structures, thus maintaining the structural integrity and indoor air quality.

The versatility of HDPE geomembrane liners has resulted in their adoption across various sectors. Their characteristics, such as chemical resistance, durability, and impermeability, make them a go-to solution for many applications.

HDPE liners are integral to modern waste management techniques:

In the mining industry, HDPE geomembranes are used for:

HDPE liners are extensively used to store water:

In agriculture, HDPE geomembranes have found several uses:

HDPE geomembranes play a crucial role in construction projects:

HDPE geomembranes are pivotal in environmental conservation projects:

For recreational purposes, HDPE geomembranes are employed in:

There are other specialized uses of HDPE geomembrane liners, including secondary containment for chemical storage, temporary containment for spills, and more.

Given the extensive applications and advantages of HDPE geomembrane liners, it’s no surprise that they’re considered an essential tool in various sectors, from agriculture to mining to urban development.

HDPE geomembrane liners have solidified their role as essential tools in various industries. Their numerous advantages lead to both direct and indirect benefits for businesses, the environment, and society at large. Delving into these advantages paints a clearer picture of the value these liners bring to the table.

HDPE geomembranes are built to last. They are resistant to UV radiation, harsh chemicals, and punctures. This robustness means that once installed, these liners provide a long-term solution with minimal maintenance. As a result, businesses can save on replacement and repair costs.

In applications like waste management or mining, HDPE liners play a crucial role in protecting the environment. They prevent contaminants from entering groundwater and other ecosystems, preserving the natural environment and safeguarding public health. The reduced risk of environmental contamination can also mean fewer liabilities for businesses.

In the long run, using HDPE geomembrane liners can prove to be cost-effective. Their installation is straightforward, reducing labor costs. The long lifespan of these liners, combined with minimal maintenance requirements, means reduced expenses over time.

HDPE geomembranes are adaptable to a variety of applications. Whether it’s lining a decorative pond, serving as a barrier in a landfill, or facilitating mining operations, their versatility ensures they cater to diverse needs across industries.

In applications like water storage or aquaculture, HDPE liners aid in effective resource management. By preventing water loss due to seepage, they ensure that resources are utilized to their fullest potential.

For construction and infrastructure projects, HDPE geomembranes can protect foundational elements from water or chemical damage, ensuring the integrity and longevity of structures.

HDPE liners in landfills not only contain waste but also aid in the collection of byproducts like methane gas. This gas, once collected, can be converted into energy, thereby turning waste into a valuable resource.

Choosing the right HDPE geomembrane liner is crucial to ensure project success. A liner ill-suited for a particular application might lead to performance issues, increased costs, and potential environmental hazards. Here’s a comprehensive guide to making the right choice:

First and foremost, you need to understand the specific requirements of your project. Is it a landfill that requires maximum impermeability? Or perhaps an aquaculture pond that needs a liner with optimal UV resistance? Pinpointing your needs will help narrow down choices.

HDPE geomembranes come in various thicknesses, typically ranging from 0.5mm to 3mm. The appropriate thickness will depend on your project’s demands. For instance, a heavy-duty application like a landfill might require a thicker liner compared to a decorative pond.

The type of soil or substrate where the geomembrane will be placed can influence your choice. For example, rougher substrates might demand a thicker or textured geomembrane to prevent potential damage.

HDPE geomembranes are chemically resistant, but certain aggressive chemicals can affect their longevity. If your project involves such chemicals, you might need to consider liners that have been specifically treated or manufactured for such environments.

If the geomembrane will be exposed to sunlight for prolonged periods, considering UV resistance becomes paramount. UV-stabilized HDPE geomembranes are manufactured to withstand the deteriorative effects of ultraviolet radiation.

Always choose a reputable manufacturer. Look for certifications, past projects, and reviews. A manufacturer with a solid track record is more likely to deliver a high-quality product.

Table: Key Factors to Consider While Choosing HDPE Geomembrane Liner

| Factor | Consideration | Importance |

|---|---|---|

| Application | Landfill, Pond, Mining, etc. | Defines specific needs |

| Thickness | Ranges from 0.5mm to 3mm | Ensures robustness |

| Soil Type | Rough, Smooth, Sandy, etc. | Influences liner type |

| Chemical Environment | Acids, Alkaline, Neutral | Dictates chemical resistance needs |

| UV Exposure | Duration and Intensity | Determines need for UV stabilization |

| Manufacturer | Reputation and Track Record | Guarantees quality and reliability |

The HDPE geomembrane industry boasts a number of reputable manufacturers worldwide. However, choosing a top-notch manufacturer can be the difference between a successful project and a costly mistake. Here are ten of the best HDPE geomembrane liner manufacturers known for quality, innovation, and reliability:

A global leader, GSE Environmental offers a wide range of geomembrane solutions. Their products are known for durability and environmental safety.

Renowned for their PondGard liners, Firestone Building Products is a trusted name in the industry, known for high-quality products.

A global company, Solmax offers innovative geomembrane solutions, ranging from traditional liners to specialized products for unique applications.

Carlisle is a trusted name, known for its dependable HDPE geomembranes, especially in construction and water containment.

This German manufacturer is at the forefront of geosynthetics. Their HDPE liners are widely used in Europe and around the globe.

Specializing in environmental protection, AGRU America provides HDPE liners that are both durable and eco-friendly.

This Greece-based company is one of the leading producers of geomembranes in Europe, with a strong emphasis on quality and innovation.

An Italian giant, Officine Maccaferri has been in the business for over a century, offering reliable geomembrane solutions.

Nilex is a North American leader, known for its environmentally-friendly geomembrane solutions.

A Canadian leader, Layfield Group offers a wide range of HDPE geomembrane liners, with a reputation for quality and service.

Selecting a manufacturer from this list guarantees you a product that has been tried and tested across numerous projects worldwide. Always remember to evaluate your specific project needs and consult with potential manufacturers to ensure the best fit for your application.

When it comes to purchasing HDPE geomembrane liners, there are several considerations to take into account. The choice of where to buy can impact the quality, price, and efficiency of the project. Given the important role geomembranes play in various industries, from agriculture to construction, it’s essential to make informed decisions.

The most direct way to purchase geomembranes is straight from the manufacturer. This ensures that you get a firsthand account of the product’s specifications, certifications, and quality guarantees. Moreover, manufacturers may offer bulk discounts, making it cost-effective for large-scale projects.

There are many distributors specializing in geosynthetics. These distributors often have ties with multiple manufacturers, which means they can provide a range of options to choose from. They might also offer value-added services, such as consultancy or customized packaging.

Online platforms like Alibaba, Amazon, and Global Sources offer listings from multiple sellers. They provide a convenient platform for comparison in terms of price, features, and customer reviews. However, due diligence is needed to ensure that the seller is reputable.

In some areas, local hardware or construction supply stores may stock HDPE geomembrane liners. This option is suitable for small-scale projects or immediate requirements. It’s also an opportunity to physically assess the product before purchasing.

Trade shows dedicated to construction, agriculture, or environmental protection often feature manufacturers and distributors of geomembranes. These events provide a unique opportunity to see the latest products, get hands-on demonstrations, and build direct relationships with suppliers.

Industry peers, consultants, or project managers might have recommendations based on their experiences. Word-of-mouth referrals can guide you towards trusted suppliers, especially if the recommendation comes from a trusted source.

Chinese manufacturers have steadily risen to prominence in the global geosynthetics industry, offering HDPE geomembrane liners that are both high in quality and cost-effective. Here’s a deep dive into why Chinese HDPE geomembrane liners stand out:

Chinese manufacturers benefit from the country’s vast manufacturing infrastructure, leading to economies of scale. This allows for competitive pricing without compromising on quality.

Over the years, Chinese factories have adopted advanced manufacturing technologies, ensuring that the HDPE geomembrane liners produced meet international standards in terms of durability and performance.

With a multitude of manufacturers, China offers a diverse range of geomembrane liners, catering to various applications, from agriculture to mining.

Many Chinese manufacturers, recognizing the global demand for quality assurance, have secured international certifications for their products. This ensures that the geomembranes are produced in accordance with global standards.

Chinese manufacturers have established robust global distribution networks. This means that regardless of where your project is located, procuring geomembranes from China is a straightforward process.

One notable advantage is the customization capability of Chinese manufacturers. They can produce geomembranes tailored to specific project needs, whether it’s in terms of size, thickness, or other unique specifications.

With growing environmental awareness, many Chinese manufacturers are ensuring that their production processes are eco-friendly, aligning with global sustainability standards.

China’s vast manufacturing landscape fosters competition and innovation. This means that Chinese HDPE geomembrane liners are often at the forefront of industry advancements, incorporating the latest features and benefits.

When speaking of top-tier geosynthetic suppliers in China, Huisen undoubtedly finds its place among the best. Huisen has carved out a niche in the industry, with a reputation built on quality, innovation, and customer satisfaction.

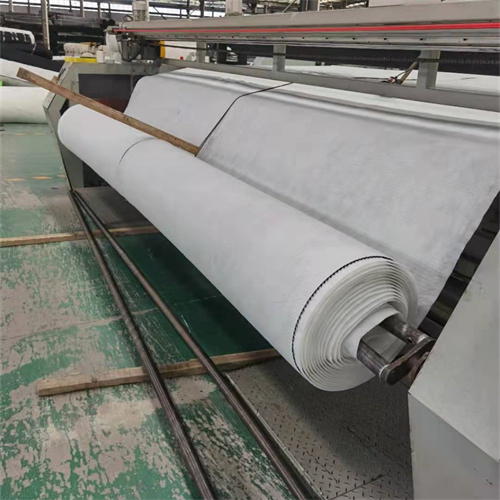

Huisen, based in China, is a specialist in the geotextile arena. With a self-owned geotextile factory, the company boasts a dedicated workforce of more than 500 employees. This manpower, combined with state-of-the-art manufacturing processes, ensures that Huisen products are of the highest quality.

Huisen’s product range isn’t limited to just HDPE geomembrane liners. They manufacture geotextiles, geomembranes, geosynthetic clay liners, and composite drainage nets. This extensive product range makes them a one-stop solution for various geosynthetic needs.

One of Huisen’s standout features is its commitment to quality. Their geotextiles are known for excellent water permeability, making them ideal for applications that require efficient water flow management.

Huisen’s focus on customer satisfaction is evident in its offerings. They provide innovative design and packaging services tailored to client needs. Their responsive and professional team ensures that customers have full-time support throughout their purchasing journey.

Recognizing the global demand for their products, Huisen has optimized its logistics for fast shipping. Additionally, they offer flexible warehouse facilities, ensuring that product storage and shipping align with customer timelines and requirements.

An HDPE geomembrane liner is a synthetic membrane liner or barrier made from high-density polyethylene (HDPE). It is widely used in various applications such as landfill linings, pond liners, and mining to prevent fluid leakage.

HDPE is favored for geomembranes due to its exceptional resistance to ultraviolet radiation, chemicals, and punctures. Additionally, its high tensile strength makes it ideal for applications that require durability and longevity.

Huisen maintains rigorous quality control processes and adheres to international standards. Their products are manufactured in a self-owned factory, overseen by a dedicated team of professionals, ensuring that each product meets or exceeds quality expectations.

Yes, Huisen is known for its flexibility in product design and packaging. They can produce geomembranes tailored to specific project needs, be it in terms of size, thickness, or other unique specifications.

Installation and handling methods can vary based on the application and project size. However, it’s essential to ensure the liner is free from sharp objects or debris that could cause punctures. Additionally, it’s beneficial to consult with the manufacturer or an expert, like Huisen’s professional team, for best practices.

The lifespan of an HDPE geomembrane liner can vary based on factors like environmental conditions and the specific application. However, with proper installation and maintenance, they can last for several decades.

While both are used as barriers, geosynthetic clay liners (GCLs) are a combination of geotextiles and bentonite clay. GCLs are used in environments where natural clay is not available or feasible. HDPE geomembranes are purely synthetic barriers made from high-density polyethylene. The choice between the two often depends on the project’s specific requirements and the desired permeability.