Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

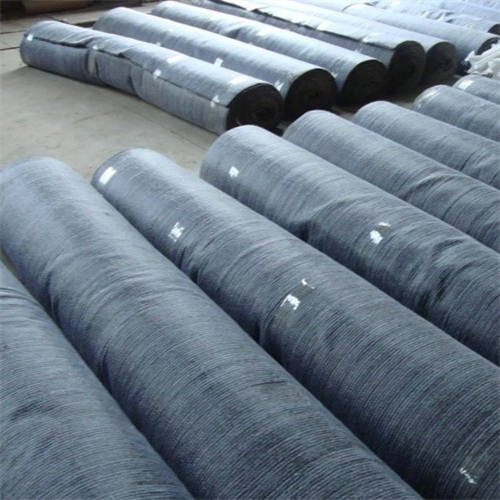

Geotextiles are permeable fabrics made from synthetic or natural fibers used in civil engineering applications. They are an important material used in construction projects for separation, reinforcement, filtration, drainage, and containment.

Choosing the right geotextile factory is crucial to get high quality geotextile materials that meet technical specifications. This guide provides a comprehensive overview of geotextile manufacturing, different types of geotextile products, key parameters, applications, installation, and tips on selecting suppliers.

Geotextiles are made by weaving, knitting, or bonding fibers together to form permeable fabrics. The raw materials used include polypropylene, polyester, polyethylene, PVC, glass fiber, and natural fibers.

The key processes in geotextile production include:

Geotextile Manufacturing Processes

| Process | Description |

|---|---|

| Raw material preparation | Raw synthetic or natural fibers are prepared and extruded into the required denier and length. |

| Web formation | Fibers are assembled into a continuous web using weaving, knitting, or bonding techniques. |

| Finishing | The fabric undergoes finishing processes like heat setting, calendaring, coating and impregnation. |

| Testing and inspection | The geotextile is tested for technical properties and inspected for defects. |

| Packaging | Finally, the fabric is cut to size and packed for transportation. |

The manufacturing method affects characteristics like strength, elongation, permeability, and cost. The quality control system, testing facilities, and reliability of the manufacturer are crucial.

Geotextiles are classified into different types based on the raw material, manufacturing method, and applications:

Geotextile Types

| Type | Description | Applications |

|---|---|---|

| Woven | Made by interlacing warp and weft fibers in a regular pattern | Roadways, railway tracks, embankments |

| Nonwoven | Made by bonding fibers through needle punching, heating, or gluing | Slopes, dams, canals |

| Knitted | Made by interlooping one or more yarns | Soil separation, silt fences |

| Composite | Made by combining above techniques | High strength needs |

| Coated | Coated with bitumen, PVC, latex, etc. | Canals, ponds, dams |

The product range includes geotextile sheets, geogrids, geonets, geocells, geocomposites, and more. The choice depends on required properties and site conditions.

Geotextiles need to meet design requirements like strength, permeability, and filtration ability. Key parameters considered are:

Geotextile Properties

| Parameter | Unit | Typical Values | Factors Affecting | Test Methods |

|---|---|---|---|---|

| Mass per unit area | g/m2 | 100 to 1000 | Fiber denier and density | ISO 9864 |

| Thickness | mm | 1 to 15 | Fabric weight and density | ISO 9863 |

| Tensile strength | kN/m | 5 to 1000 | Fibers, construction method | ISO 10319 |

| Elongation | % | 10 to 30 | Polymer type, crimp | ISO 10319 |

| CBR puncture resistance | N | 100 to 10000 | Reinforcement | ISO 12236 |

| Permeability | cm/sec | 0.1 to 5 | Pore size, openings | ISO 11058 |

| Filtration opening size | μm | 70 to 300 | Fiber denier, construction | ISO 12956 |

| UV resistance | % strength retained | 50 to 90 | Additives, coatings | ISO 12224 |

| Durability | Years | 5 to 100 | Polymer, antioxidants | ISO 13438 |

The product should meet the highest specifications as per recognized international test standards.

Geotextiles have a wide range of civil engineering applications:

Geotextile Applications

| Application | Functions | Types Used |

|---|---|---|

| Road construction | Separation, filtration, reinforcement | Nonwoven, woven |

| Railway beds | Filtration, drainage, separation | Nonwoven |

| Retaining walls | Reinforcement, drainage | Woven, composite |

| Slopes | Reinforcement, erosion control | Nonwoven, knitted |

| Embankments | Filtration, separation, drainage | Nonwoven |

| Canals | Seepage control, bank protection | Nonwoven, coated |

| Reservoirs | Seepage control, protection | Nonwoven, coated |

| Dams | Filtration, drainage, separation | Nonwoven |

| Landfills | Separation, drainage, liner | Composite, coated |

Geotextiles perform various functions like filtration, separation, reinforcement, drainage, and erosion control in these applications.

The design of geotextiles requires consideration of:

The product specifications should meet the highest standards for the design life of the application.

Correct installation procedures are vital for geotextiles to function effectively:

Geotextile Installation Guide

| Parameter | Recommendations |

|---|---|

| Site preparation | Clear vegetation, sharp objects, and level uneven surfaces |

| Underlayer | Place geotextile on prepared subgrade or cover uneven ground |

| Placement | Roll out geotextile smoothly without wrinkles or folds |

| Overlaps | Overlap geotextile joints by 300-600 mm and secure with adhesive, pins, or soil fill |

| Protection | Avoid damage by sharp equipment, boots, or falling objects during placement |

| Fill placement | Place fill material slowly and uniformly over geotextile in thin layers |

| Compaction | Use light compaction minimizing direct contact with geotextile |

| Drainage | Provide adequate drainage layers, pipes, geonets if required |

| Repair | Inspect for damages and repair by adding geotextile patch extending 1 m beyond damaged area |

Following manufacturer’s guidelines on overlaps, underdrainage, placement below/above fill material is recommended.

Geotextiles generally do not require maintenance once installed. However, the following should be ensured:

This helps prevent clogging and continue effective functioning of the geotextile.

The key factors in selecting a geotextile supplier are:

How to Choose Geotextile Manufacturer

| Parameter | Recommendations |

|---|---|

| Reputation | Established company with proven track record |

| Certifications | ISO certifications for quality management |

| Manufacturing capability | Advanced production machinery, process controls |

| Testing capability | Full-fledged lab for quality checks and documentation |

| Product range | Diverse geotextile and geosynthetics range |

| Customization | Ability to customize products as per specifications |

| Technical expertise | Experienced engineers and technical personnel |

| Logistics | Ability to deliver globally via warehouses, prompt lead times |

| Pricing | Cost-effectiveness for quality products |

| Documentation | Complete test reports provided for each batch |

| Service | Responsive customer service and technical support |

Getting samples tested independently as per design needs is recommended.

Typical price ranges for geotextile materials based on polymer type are:

Geotextile Pricing

| Polymer Type | US$ per sq.m |

|---|---|

| Polypropylene | 0.5 – 1.5 |

| Polyester | 1 – 2.5 |

| Polyethylene | 1.5 – 3 |

| Glass fiber | 2 – 5 |

| Natural fibers | 2 – 10 |

Polypropylene geotextiles offer optimal cost-effectiveness whereas glass fiber and natural fibers are more expensive.

Cost also depends on weight, thickness, manufacturing method, and order quantity. Large volume orders usually cost 20-30% lower than small quantities.

Geotextile Material Comparison

| Parameter | Polypropylene | Polyester | Polyethylene | Glass Fiber | Jute |

|---|---|---|---|---|---|

| Strength | Medium | High | Medium | Very high | Low |

| Durability | High | Medium | Medium | Medium | Low |

| Permeability | High | Medium | Low | High | High |

| Temperature resistance | Medium | High | Low | High | Low |

| UV resistance | Medium | High | Low | High | Low |

| Cost | Low | Medium | Medium | High | Medium |

Polypropylene geotextiles offer optimal overall performance at low cost. Jute and glass fiber are suited for specialized applications. Polyester provides good strength and durability.

Some limitations of geotextiles:

Proper product selection and installation methods can mitigate these limitations.

Q: What are the different geotextile manufacturing methods?

A: The main manufacturing methods are weaving, knitting, and nonwoven through bonding. Each method produces geotextiles with different characteristics suited for certain applications.

Q: Should geotextiles be placed above or below fill material?

A: Geotextiles are typically placed directly on the subgrade below the fill material. But for drainage applications, they may be placed between layers or above fill material.

Q: How to prevent geotextile erosion in high flow drainage areas?

A: Use adequate cover fill thickness, limit gradient, or use hard armoring. High strength woven or composite geotextiles can also withstand higher shear forces.

Q: What is the typical width of geotextile rolls?

A: Standard geotextile roll widths range from 5 m to 12 m. Wider rolls result in fewer overlaps and faster installation.

Q: How to repair damages in installed geotextiles?

A: Damaged areas can be repaired by adding a geotextile patch extending at least 1 m beyond the damaged section.

Q: What is the service life of geotextiles?

A: Properly selected geotextiles can last 25 to 50 years. Factors affecting life include polymer type, additives, installation, and site conditions.

Q: Are biodegradable geotextiles available?

A: Yes, geotextiles made from natural fibers like jute and coir are biodegradable options, but have lower strength and durability.

Q: Does geotextile filtration ability decrease over time?

A: Yes, partial clogging by fine soil particles can occur over time. Proper drainage design mitigates this. Maintenance to remove sediment buildup helps.

Q: What are the benefits of using woven vs nonwoven geotextiles?

A: Woven geotextiles have higher strength but lower permeability. Nonwovens have better filtration and drainage capacity.