Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

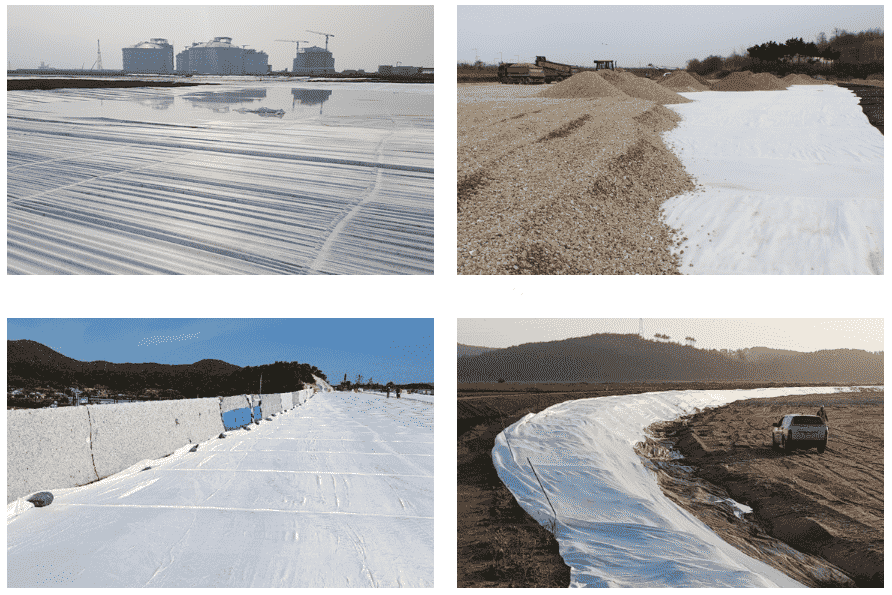

Geotextiles are permeable fabrics made from synthetic fibers that are used in a variety of applications related to soil, foundations, erosion control, drainage, and construction. This comprehensive guide provides an overview of geotextile products, characteristics, applications, suppliers, costs, installation, and more for wholesale purchasing and projects.

Geotextiles provide separation, filtration, drainage, and reinforcement functions using woven, nonwoven, or knitted constructions. Key properties and benefits include:

Geotextiles are a versatile solution for many geo-construction and environmental applications. They are often more cost-effective and sustainable than traditional hard construction materials.

| Application | Description |

|---|---|

| Roadways | Subgrade and subbase separation and stabilization |

| Erosion Control | Temporary and permanent control measures |

| Drainage | Subsurface drainage systems, retaining wall drains |

| Landfills | Gas venting, leachate and drainage layers |

| Foundations | Slabs, walls, liquefaction mitigation |

| Coastal Structures | Under revetments, buried seawalls |

| Canals | Bank protection, structural support |

There are three primary types of geotextile fabrics used in construction and engineering projects:

Key properties and specifications vary based on geotextile type and composition:

| Parameter | Typical Values | Factors Affecting | Test Methods |

|---|---|---|---|

| Weight | 150-800 g/m2 | Fiber denier and density | ASTM D5261 |

| Thickness | 1-15 mm | Fiber volume and compression | ASTM D5199 |

| Strength | 5-200 kN/m | Fiber material and construction | ASTM D4595 |

| Permittivity | 0.1-3.0 sec−1 | Voids between fibers | ASTM D4491 |

| Water Flow Rate | 10-150 l/min/m2 | Porosity and hydraulic gradients | ASTM D4491 |

| Apparent Opening Size | 0.06-1.0 mm | Fiber dimensions and spacing | ASTM D4751 |

| UV Resistance | 50-90% strength retained after 500 hrs | Additives and coatings | ASTM D4355 |

Polypropylene geotextiles offer adequate performance at low cost but have lower strength and durability compared to polyester. Polyvinyl alcohol (PVA) geotextiles provide high filtration performance. composite chemical irradiation One stop supplier

Many major geosynthetics manufacturers supply geotextile fabrics for wholesale, including:

Major Geotextile Manufacturers

When selecting a geotextile supplier, consider:

Wholesale geotextile fabric pricing depends on:

Typical Geotextile Pricing

| Geotextile Type | Polypropylene Price Range | Polyester Price Range |

|---|---|---|

| Nonwoven | $0.20 – $1.50 per m2 | $0.50 – $2.50 per m2 |

| Woven | $0.60 – $2.00 per m2 | $1.50 – $4.00 per m2 |

Contact major geotextile suppliers directly for wholesale quotations on specific product grades and order quantities. Expect minimum order volumes around 5000 m2.

Correct installation procedures must be followed to achieve desired performance. Key guidelines include:

Proper installation ensures the geotextile performs correctly. Soil and vehicle movement can damage fabric. Careful material handling prevents tear propagation.

Geotextiles require minimal maintenance once installed properly. Key considerations include:

Proactive inspection and maintenance ensures geotextiles continue providing soil reinforcement, separation, filtration and drainage over the design life.

Selecting the optimal geotextile depends on the application and site conditions:

Key Selection Factors

Obtain soil data through geotechnical investigation. Consult with geotextile suppliers and specification guidelines to select suitable products. Consider potential long-term changes in site conditions.

Geotextile polymers have relative advantages and disadvantages:

| Parameter | Polypropylene | Polyester | Polyvinyl Alcohol | Glass Fiber |

|---|---|---|---|---|

| Strength | Medium | High | Low | Very high |

| Durability | Low-medium | High | Medium | High |

| UV resistance | Low | High | Low | High |

| Filtration | Medium | Low | High | Medium |

| Cost | Low | Medium | High | High |

| Chemical resistance | Medium | High | Low | High |

| Elongation | Medium | Low | High | Low |

Polypropylene geotextiles offer adequate versatility at low cost. Polyester has higher chemical and UV resistance. PVA excels in filtration applications. Fiberglass geotextiles provide very high strength and durability.

Advantages of Geotextiles:

Disadvantages of Geotextiles:

Geotextiles are not suitable for every scenario. However, they offer a versatile and sustainable alternative to traditional materials in many situations. Consider key parameters during selection and design.

Geotextiles offer versatile, cost-effective solutions for filtration, separation, drainage and reinforcement across geoconstruction applications ranging from road building to landfills. Wholesale geotextile purchasing can provide significant material savings on major projects. Work closely with reputable suppliers to select the proper geotextile products based on technical parameters and design needs. Following best practices for installation and maintenance ensures geotextiles achieve target service life. Consider geotextiles as a sustainable construction alternative to conventional materials in many situations.

Q: Are geotextiles recyclable?

A: Most geotextiles are made from polypropylene or polyester which are recyclable materials. However, geosynthetics containing mixtures of fibers and coatings are more difficult to recycle. Reusing removed geotextiles onsite as erosion control blankets or similar is recommended.

Q: Can geotextiles be used for slope stabilization?

A: Yes, woven high strength geotextiles anchored into the slope can reinforce the soil structure and stabilize steep slopes prone to failure and landslides. Proper design is crucial.

Q: What is the design life of geotextiles?

A: Expected geotextile lifetime depends on material composition, application, and site conditions. Polypropylene geotextiles last 5-15 years typically while polyester can exceed 50 years. UV exposure, chemicals, and stress shorten service life.

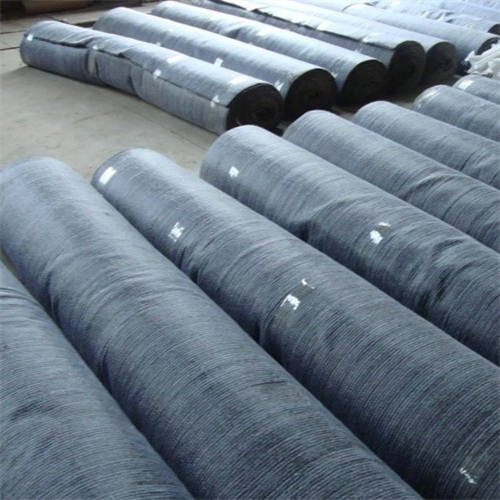

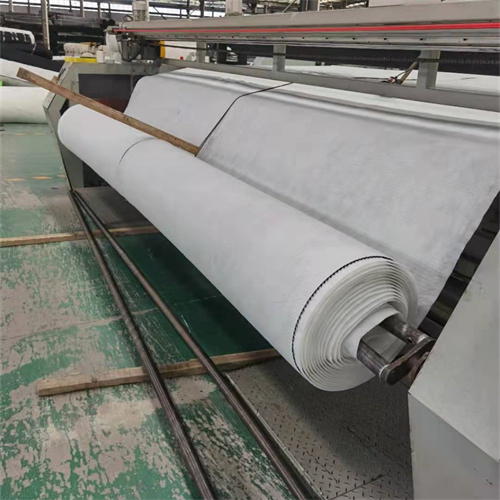

Q: How are geotextiles delivered to site?

A: Geotextiles typically come in large rolls 3-4 meters wide and 25-200 meters long. Trucks deliver on pallets or trailers. Fabric offloading requires forklifts and spreader bars for safe handling.

Q: Can geotextiles have antimicrobial properties?

A: Yes, certain geotextiles are available with antimicrobial treatments such as silver ion technology and organic biocides. These are used when microbiological growth could compromise performance.