Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

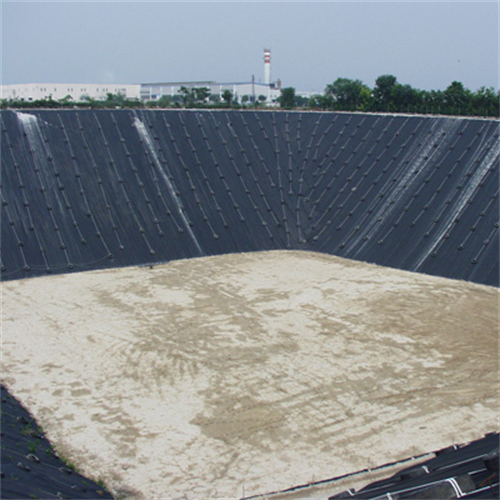

Geotextiles are versatile geosynthetic materials used in many civil engineering and construction applications. When used for waterproofing, geotextiles provide a water barrier while still allowing water vapor transmission. This makes them an ideal material for below-grade waterproofing.

Geotextiles are available in different forms including woven, nonwoven, knitted, and composite. The type of geotextile selected depends on the application and performance requirements. This article provides a comprehensive overview of using geotextiles for below-grade waterproofing.

Geotextiles are made from synthetic polymer fibers such as polypropylene, polyethylene, polyester, or polyamide. The table below shows the typical composition of different geotextile types:

| Geotextile Type | Typical Polymer Fibers Used |

|---|---|

| Woven | Polypropylene, Polyester |

| Nonwoven | Polypropylene, Polyester |

| Knitted | Polypropylene, Polyester, Polyamide |

| Composite | Combination of above polymers |

The polymer fibers provide strength, chemical resistance, and long-term durability in ground conditions. Manufacturing methods like needle punching, heat bonding, and resin treatment produce a range of physical characteristics for different applications.

Geotextiles exhibit certain key properties that make them suitable for below-grade waterproofing.

| Property | Function |

|---|---|

| Minimum grab tensile strength | Provides resistance against installation damage and in-situ soil stresses |

| Trapezoidal tear strength | Resistance against puncture and tearing |

| Apparent opening size | Acts as a filtration layer while allowing water passage |

| Water permeability | Allows water drainage while blocking soil passage |

| Chemical resistance | Long-term durability against soil chemicals, microbes, and pH |

| UV resistance | Ability to withstand sunlight exposure during installation |

Proper geotextile selection ensures required performance levels for these properties. Testing is done as per standardized test methods.

Geotextiles are used in below-grade waterproofing systems for:

They provide waterproofing, drainage, and protection from moisture damage and hydrostatic pressure buildup.

The table below compares different geotextile types and their typical use in waterproofing applications:

| Geotextile Type | Key Properties | Typical Waterproofing Applications |

|---|---|---|

| Nonwoven | High water flow capacity, moderate puncture resistance | Retaining walls, foundation walls |

| Woven | High tensile strength, tear resistance | Landfill liners, harsh installation conditions |

| Composite | Combines properties of woven and nonwoven | Tunnels, below concrete slabs |

| Bentonite clay geotextile | Self-sealing ability | Below-grade walls, secondary water barrier |

Project specifications dictate which geotextile type provides the required performance level most cost-effectively.

Geotextiles used for below-grade waterproofing must meet minimum material specifications as per standards like ASTM D4439, ASTM D5261, and ASTM D6707.

| Parameter | Specification Requirements |

|---|---|

| Grab tensile strength | 400-1200 lbs, depending on application |

| Trapezoidal tear strength | 100-250 lbs |

| Apparent opening size | ≤ 0.3 mm for fine soils |

| Permeability | 0.5 – 15 gallons/min/ft2 |

| UV resistance | 50-70% strength retained after 500 hours |

Other key specifications include geotextile roll weight, roll dimensions, and polymer material requirements.

Many reputable manufacturers offer geotextile products for waterproofing uses. Some popular options include:

| Product | Key Features |

|---|---|

| Mirafi 140N | Versatile nonwoven for walls and foundations |

| Carthage Mills FX-40HS | High strength woven with cross-machine direction |

| Stratatex ST142 | Composite geotextile for harsh installation |

| CETCO SeamGrip | Polypropylene bentonite clay waterproofing membrane |

Pricing depends on product specifications and order quantity. Contact manufacturers for current cost details.

To maintain geotextile integrity, proper handling and storage is essential:

Cover geotextiles with opaque protective sheeting on site. Follow any additional handling guidelines from the manufacturer.

Workers must take safety precautions during geotextile installation:

Adequate ventilation should be provided in enclosed areas. Requirements per OSHA standards must be met.

Geotextiles must be inspected upon delivery and tested before installation:

| Inspection Checks | Test Methods | Acceptance Criteria |

|---|---|---|

| Proper product type | ASTM D4632 – Grab tensile test | Per project specification |

| No defects or damage | ASTM D4533 – Trapezoid tear test | Per project specification |

| Roll labels and product ID | ASTM D4751 – Apparent opening size | Per project specification |

| Storage conditions | ASTM D4491 – Water permeability test | Per project specification |

All geosynthetics testing must be done in an accredited lab. Defective or deficient materials must be replaced.

Correct installation procedures are vital for geotextile waterproofing function:

Follow manufacturer guidelines and project specifications closely.

When properly selected and installed, geotextiles provide reliable below-grade waterproofing performance:

Advantages:

Limitations:

Regular inspections help detect any deficiencies for repair. Overall, geotextiles present excellent long-term value for below-grade waterproofing.

Geotextiles present an excellent waterproofing solution for below-grade structures. Their filtration capability manages groundwater contact while allowing vapor transmission. A range of geotextile products with specific performance properties are available. Following proper design, handling, installation, and inspection procedures is critical. Geotextile waterproofing provides long-term durability, performance value, and safety across many construction applications.

Q: How does geotextile provide waterproofing compared to other materials?

A: Geotextiles waterproof by blocking passage of fine soil particles while allowing water flow. This is different from plastic sheets that act as total water barriers. The geotextile filtration mechanism prevents hydrostatic pressure buildup.

Q: What type of soil conditions are unsuitable for geotextile waterproofing?

A: Geotextiles are not recommended for soils with high percentage of coarse gravel or sharp rocks that may damage the geotextile. High groundwater flow velocities above 15 gallons/min/ft2 are also unsuitable.

Q: How are seams and overlaps sealed in geotextile waterproofing applications?

A: Seams can be sealed by adhesives, thermally bonded strips, or bentonite fillers. Typical overlaps are 6-12 inches. Soil backfill also helps seam sealing.

Q: Does geotextile waterproofing require maintenance?

A: Minimal maintenance is needed if installed correctly. Regular inspections help detect defects for repair. Maintenance access should be provided to critical areas.

Q: How long does geotextile waterproofing last compared to other methods?

A: Properly installed geotextiles can have 50+ year design life. This exceeds plastic membranes and bituminous coatings. Longevity depends on polymer resistance to soil environment.