Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

Address

Mengshan Road, Wenyang Industrial Park, Laiwu District, Jinan City, Shandong Province

Phone

+86 151 6634 6139

[email protected]

[email protected]

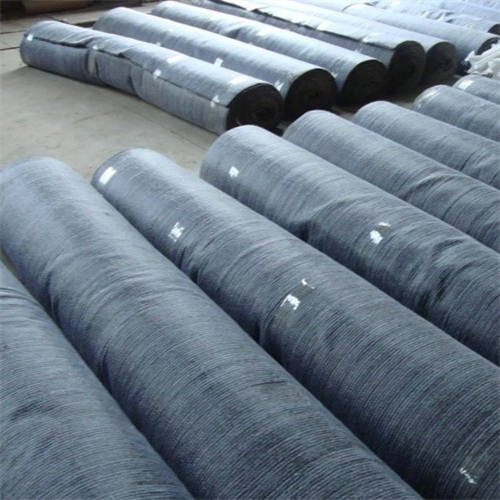

Geotextile fabric is a type of permeable fabric that is primarily used in geotechnical and civil engineering applications. Made from polymeric materials such as polyester or polypropylene, geotextile fabrics come in woven, non-woven, and knitted forms.

These fabrics have a multitude of uses, but their primary function is to separate, stabilize, filter, reinforce, protect, or drain. They are commonly used in construction sites, agricultural fields, and infrastructure projects to enhance the performance of soils and aggregates.

Types of Geotextile Fabric:

Uses in Civil Engineering:

Geotextile fabrics are extensively used in various civil engineering projects. Some common uses include:

| Advantages | Disadvantages |

|---|---|

| Provides stability to soil | Can be damaged by UV exposure |

| Enhances drainage | Might be expensive for larger projects |

| Reduces erosion | Requires proper installation techniques |

In conclusion, geotextile fabric is an essential tool in the world of civil engineering, playing a vital role in ensuring that projects are structurally sound and environmentally sustainable.

The cost of geotextile fabric varies widely based on type, quality, manufacturer, and region. These fabrics are sold either by the roll or by the square yard/meter, and the price can range from very affordable to quite expensive depending on the specific application and requirements.

Factors Affecting Cost:

Price Range:

Here’s a general price range for geotextile fabrics based on their type:

| Type | Price per square meter |

|---|---|

| Woven | $0.50 – $2.00 |

| Non-Woven | $0.30 – $1.50 |

| Knitted | $0.60 – $2.50 |

Top Brands and Their Price Range:

When considering the cost of geotextile fabric, it’s essential to also factor in the costs of installation, maintenance, and potential replacements. Always consult with a specialist or manufacturer to get accurate pricing and ensure you’re selecting the right fabric for your specific needs.

Geotextile fabrics are specially engineered to meet a variety of needs in civil engineering and construction projects. These textiles are categorized based on their manufacturing process and the application they are intended for. Here’s a comprehensive overview:

1. Woven Geotextile:

2. Non-Woven Geotextile:

3. Knitted Geotextile:

| Type | Manufacturing Process | Primary Application | Price per square meter |

|---|---|---|---|

| Woven | Weaving of threads | Soil stabilization | $0.50 – $2.00 |

| Non-Woven | Bonding/Entangling fibers | Filtration & Protection | $0.30 – $1.50 |

| Knitted | Interlooping of yarns | Erosion control | $0.60 – $2.50 |

When selecting a geotextile fabric, understanding its type and primary function is crucial. Always consult with experts or manufacturers for guidance tailored to specific project needs.

Geotextile fabrics have been instrumental in the advancement of modern civil engineering projects. These fabrics offer a versatile range of functions, playing a vital role in enhancing the performance and longevity of infrastructure projects.

1. Separation:

2. Reinforcement:

3. Filtration:

4. Drainage:

5. Protection:

6. Erosion Control:

Each of these functions highlights the essential role geotextile fabrics play in ensuring the success of various civil engineering projects.

The versatility of geotextile fabrics has led to their widespread use in an array of applications across the civil engineering and construction sectors. Each type of geotextile, be it woven, non-woven, or knitted, has been uniquely engineered to address specific challenges. Here’s a deep dive into the myriad applications of these fabrics:

1. Road Construction:

Geotextiles are fundamental in road construction. They prevent the intermixing of different layers, provide strength and stability, and enhance drainage. This ensures the longevity of roads, even in areas with weak soil or high water tables.

2. Railways:

Much like in road construction, geotextiles are employed in railway tracks to segregate ballast from the underlying soil, ensuring the stability and functionality of the tracks over time.

3. Erosion Control:

In areas prone to erosion, such as riverbanks, shorelines, and steep slopes, geotextile mats or nets are used. They hold the soil in place, facilitate vegetation growth, and protect against the erosive forces of wind and water.

4. Landfills:

Geotextiles play a dual role in landfills. They protect the geomembranes from getting punctured, and they also facilitate effective drainage, ensuring the swift removal of any leachate or gases.

5. Retaining Walls and Embankments:

When building vertical or near-vertical structures, geotextiles offer reinforcement, preventing the soil or aggregate from collapsing. This is crucial in areas with soft or unstable soils.

6. Drainage Systems:

Geotextiles can wrap around drainage pipes, acting as a filter and preventing the clogging of the pipes by fine soil particles. This ensures the longevity and efficiency of drainage systems.

7. Agriculture:

In agriculture, geotextiles can help in soil moisture retention, weed control, and erosion prevention. They can also act as barriers, protecting plant roots from pests.

8. Coastal and Riverbank Protection:

Areas constantly battered by waves or fast-flowing water require additional protection. Geotextile bags filled with sand or soil can act as barriers, reducing the impact of waves and preventing erosion.

| Application | Type of Geotextile | Function |

|---|---|---|

| Road Construction | Woven & Non-Woven | Separation, Reinforcement, Drainage |

| Railways | Woven | Separation, Stability |

| Erosion Control | Non-Woven & Knitted | Protection, Filtration |

| Landfills | Non-Woven | Protection, Drainage |

| Retaining Walls | Woven | Reinforcement |

| Drainage Systems | Non-Woven | Filtration, Drainage |

| Agriculture | Non-Woven | Moisture retention, Pest barrier |

| Coastal Protection | Woven & Non-Woven | Erosion control, Impact reduction |

Incorporating geotextiles into these applications brings about enhanced efficiency, reduced maintenance costs, and increased lifespan of the structures or systems in question. Their ability to tackle diverse challenges, from erosion control in coastal areas to reinforcement in road construction, emphasizes their indispensability in modern construction and engineering.

The introduction of geotextile fabric has revolutionized the construction and civil engineering world. These robust and versatile fabrics offer multiple advantages, and understanding these can shed light on why they are increasingly becoming indispensable in various projects.

1. Cost-Effective Solution:

Geotextiles provide an affordable alternative to traditional construction methods. For example, in road construction, they can reduce the thickness of the aggregate layer, leading to material savings.

2. Enhanced Durability:

Incorporating geotextiles in construction projects can significantly enhance the lifespan of structures. They offer protection against erosion, reduce stress on retaining walls, and stabilize soil, ensuring longevity.

3. Improved Drainage:

Geotextile fabrics allow water to pass through while holding back soil, sediments, and other particles. This unique property makes them perfect for drainage applications, preventing waterlogging in areas like roads, gardens, and fields.

4. Soil Stabilization:

In areas with weak or unstable soil, geotextiles can provide the much-needed reinforcement. They distribute loads evenly, preventing soil displacement or sinking, especially under heavy structures or traffic.

5. Erosion Control:

Especially in vulnerable areas like riverbanks or coastlines, geotextiles can act as a protective barrier, holding soil in place and reducing the detrimental impacts of wind and water erosion.

6. Environmental Protection:

In applications such as landfills, geotextiles help in containing harmful substances, preventing them from leaching into the surrounding environment. This is crucial for ensuring environmental safety and adhering to regulatory standards.

7. Simplified Installation:

Unlike some traditional methods, installing geotextiles is relatively straightforward. Their flexibility and lightweight nature make them easy to transport, handle, and deploy, saving both time and labor costs.

The choice of geotextile fabric is pivotal for the success of any construction or civil engineering project. Given the plethora of options available, making an informed decision can be a daunting task. This guide aims to demystify the selection process, providing clarity on the essential factors to consider.

1. Understand the Application:

The primary step in selecting the right geotextile is understanding its intended application. Is it for drainage, erosion control, soil stabilization, or a combination of these? Each function might require a different type of geotextile.

2. Consider Material Type:

Geotextiles can be made from various materials, including polypropylene, polyester, and polyethylene. The choice of material often dictates properties like UV resistance, chemical compatibility, and tensile strength. It’s vital to select a material that suits the environmental conditions of the project.

3. Assess the Mechanical Properties:

4. Evaluate Hydraulic Properties:

For projects where water management is essential, understanding the fabric’s hydraulic properties is crucial. This includes:

5. Longevity and Durability:

If the geotextile is meant for a permanent structure, it’s crucial to opt for a product that can resist factors like UV radiation, chemicals, and microbial attacks. This ensures that the geotextile remains functional for its intended lifespan.

6. Cost and Availability:

While it’s essential to opt for a quality product, budgetary constraints cannot be ignored. It’s a balancing act between quality and cost. Additionally, considering the product’s availability can prevent project delays.

| Factor | Consideration | Example |

|---|---|---|

| Application | Drainage, Erosion control, Soil stabilization | Opt for non-woven for drainage |

| Material Type | Polypropylene, Polyester, Polyethylene | Polyester for UV resistance |

| Mechanical Properties | Tensile strength, Puncture resistance | High tensile strength for reinforcement |

| Hydraulic Properties | Permeability, Pore size | High permeability for effective drainage |

| Durability | UV resistance, Chemical resistance | UV-resistant types for exposed areas |

| Cost & Availability | Budget, Supplier proximity | Local suppliers to reduce shipping costs |

Choosing the right geotextile can seem overwhelming, but a systematic approach, keeping in mind the above factors, can simplify the process. Engaging with manufacturers or experts can also provide tailored recommendations for specific project needs.

As the demand for geotextile fabrics continues to grow, many manufacturers globally have stepped up to the plate, offering a variety of products tailored to diverse needs. This article seeks to spotlight ten of the most reputed geotextile fabric manufacturers, known for their quality, innovation, and reliability.

1. TenCate Geosynthetics:

A global leader, TenCate is renowned for its innovative solutions and high-quality geotextile products. With a presence across continents, they cater to both small-scale and mega projects.

2. Fibertex Nonwovens:

Originating from Denmark, Fibertex has established itself as a frontrunner in the non-woven geotextile sector. Their commitment to sustainability and eco-friendly products sets them apart.

3. GSE Environmental:

Specializing in geosynthetic solutions, GSE Environmental offers a range of geotextile products tailored to environmental protection and containment.

4. Huesker:

A German giant, Huesker is synonymous with quality and durability. They offer a broad spectrum of geotextile products, catering to various construction and engineering needs.

5. Propex Operating Company:

With a history spanning over a century, Propex is a trusted name in the world of geotextiles. Their products are known for their reliability and top-notch performance.

6. NAUE GmbH & Co. KG:

NAUE is a pioneer in the field of geosynthetics. Their geotextile products have been instrumental in many landmark projects around the globe.

7. Maccaferri:

An Italian stalwart, Maccaferri, has a rich history in engineering solutions. Their geotextile offerings are backed by rigorous research and innovation.

8. Terram (a Berry Plastics company):

Terram has carved a niche for itself in the geotextile world, offering products that balance quality and affordability. As a part of Berry Plastics, their reach and influence have expanded globally.

9. Strata Systems:

Strata is a recognized leader in soil reinforcement technologies. Their geotextile products are integral to many infrastructure projects worldwide.

10. Typar (a Berry Plastics company):

Another feather in Berry Plastics’ cap, Typar is known for its versatile geotextile solutions that cater to a range of applications.

| Manufacturer | Origin | Specialization |

|---|---|---|

| TenCate Geosynthetics | Global | Diverse geotextile solutions |

| Fibertex Nonwovens | Denmark | Non-woven geotextiles |

| GSE Environmental | USA | Environmental protection |

| Huesker | Germany | Quality and durability |

| Propex | USA | Reliable geotextile products |

| NAUE GmbH | Germany | Pioneering geosynthetics |

| Maccaferri | Italy | Engineering solutions |

| Terram | UK | Quality and affordability |

| Strata Systems | USA | Soil reinforcement |

| Typar | USA | Versatile geotextile solutions |

As the world of construction and civil engineering evolves, the role of geotextile fabrics becomes even more paramount. These manufacturers, with their commitment to quality and innovation, ensure that projects around the world benefit from the best geotextile solutions available.

In the evolving world of construction and engineering, geotextile fabrics play a pivotal role in many projects. With this increasing demand, there’s a need to know where to procure these materials efficiently and reliably.

1. Local Distributors:

Many towns and cities have local suppliers or distributors that stock geotextile fabrics. They are a convenient option as they often offer immediate availability and reduced shipping costs.

2. Directly from Manufacturers:

Many major geotextile manufacturers, such as TenCate Geosynthetics and Huesker, provide direct sales to larger buyers. Purchasing directly can often mean reduced costs and a guarantee of product authenticity.

3. Online Marketplaces:

Sites like Alibaba, Amazon, and eBay host multiple sellers offering geotextile fabrics. These platforms allow for a comparison of prices, product specifications, and reviews, ensuring you get the best deal.

4. Specialty Stores:

Some stores specialize in construction and engineering materials. These specialty stores often have experts on hand to provide advice on the best geotextile for specific applications.

5. International Trade Fairs:

Trade fairs dedicated to construction and geosynthetics offer a unique opportunity to meet multiple manufacturers and distributors in one place. This is an excellent way for bulk buyers to negotiate deals and establish long-term business relationships.

6. Industry Recommendations:

Often, the best insights come from peers in the industry. Networking and seeking recommendations can point you to trusted suppliers and top-quality products.

Chinese geotextile fabrics have been making a significant mark in the global market, and there are several reasons for this dominance. From cost-effectiveness to high quality, the advantages of opting for Chinese-made geotextiles are many.

1. Cost-Effective Production:

Chinese manufacturers have mastered the art of producing high-quality geotextiles at a fraction of the cost, thanks to economies of scale and efficient production methods.

2. Advanced Manufacturing Techniques:

Many Chinese factories, including Huisen, employ state-of-the-art manufacturing techniques ensuring the production of top-tier geotextiles that meet international standards.

3. Variety and Customization:

China’s vast manufacturing landscape means there’s a wide variety of geotextiles available. Whether it’s non-woven, woven, or a specialized geotextile product, there’s a high chance a Chinese manufacturer produces it. Moreover, companies like Huisen offer innovative design and packaging services tailored to client needs.

4. Extensive Testing and Quality Control:

Chinese geotextile fabrics undergo rigorous testing to ensure they meet the necessary specifications. This commitment to quality ensures that the products are durable, reliable, and fit for purpose.

5. Export-Oriented:

Chinese geotextile manufacturers are well-versed in international trade, offering streamlined export processes, efficient shipping, and flexible warehousing facilities. Huisen, for instance, ensures fast shipping with its dedicated team available full-time.

6. Rapid Innovation:

Chinese manufacturers are quick to adapt to new technologies and methodologies. This adaptability means that they are often at the forefront of introducing innovative products to the market.

7. Eco-Friendly Options:

With the growing demand for sustainable construction materials, many Chinese manufacturers, including Huisen, are offering eco-friendly geotextile options that are both durable and environmentally responsible.

8. Comprehensive Service:

It’s not just about the product; it’s about the overall service. Companies like Huisen ensure a holistic approach, right from understanding client needs to post-sale support, ensuring client satisfaction at every step.

When discussing the best Chinese geotextile fabric suppliers, the name Huisen invariably comes up. This China-based powerhouse has etched a reputation for itself in the realm of geosynthetics. Here’s a deeper dive into what makes Huisen stand out:

1. Diverse Product Range:

Huisen specializes in a broad spectrum of products including geotextile, geomembrane, geosynthetic clay liner, and composite drainage net. This diverse range ensures that clients have access to a comprehensive suite of geosynthetic solutions under one roof.

2. Focus on Quality:

At the heart of Huisen’s operations is an unwavering commitment to quality. Their geotextile products boast excellent water permeability, a testament to the meticulous manufacturing processes in place.

3. Innovative Design and Packaging:

Huisen doesn’t just stop at manufacturing; they offer innovative design and packaging services tailored to client specifications. This attention to detail ensures that clients receive products that align seamlessly with their project requirements.

4. Efficient Shipping and Warehousing:

One of the hallmarks of a top-tier supplier is the ability to deliver products promptly. Huisen excels in this department, offering fast shipping coupled with flexible warehousing facilities, ensuring that clients get their products on time, every time.

5. Dedicated Professional Team:

Behind every successful company is a team of dedicated professionals, and Huisen is no exception. Their team, available full-time, works with utmost dedication and care, ensuring that client needs are addressed promptly and efficiently.

For those in the market for high-quality geotextile fabrics, Huisen stands as a beacon of reliability, quality, and excellence in the realm of geosynthetic products.

Geotextile fabric is a permeable textile material used in civil engineering and construction projects to improve soil strength and offer filtration, drainage, separation, and protection. It can be made from synthetic fibers like polyester or polypropylene and comes in woven, non-woven, or knitted forms.

Huisen is a renowned Chinese geotextile supplier known for its commitment to quality and customer satisfaction. They offer a diverse range of geosynthetic products, innovative design, and packaging services, efficient shipping, and a dedicated professional team to address your requirements.

Geotextile fabric enhances the performance and lifespan of construction projects by providing separation (preventing the intermixing of dissimilar materials), filtration (allowing for fluid passage while preventing soil erosion), drainage (channeling fluids away), and reinforcement (improving the soil’s physical properties).

Absolutely! Many of Huisen’s geotextile offerings are environmentally responsible, aligning with the growing demand for sustainable construction materials.

The choice depends on your project’s requirements. Factors like the type of soil, the intended function (filtration, separation, reinforcement, or drainage), and project scale come into play. Consulting with Huisen’s team can provide expert guidance tailored to your specific needs.

Chinese geotextile fabrics, especially from reputable suppliers like Huisen, are manufactured following international standards. With rigorous quality control processes and advanced manufacturing techniques, they are not only comparable but often exceed the quality of products from other countries.

The lifespan of geotextile fabric varies based on the type, the quality of manufacturing, and the environmental conditions it’s exposed to. However, quality geotextiles from suppliers like Huisen are designed to last for many years, ensuring longevity and durability in construction projects.